As the trucking industry looks towards the future, electrification is becoming an increasingly important topic. While the transition to electric commercial fleets has yet to reach a tipping point, it is crucial for companies to be prepared for the shift.

Samsara executives share their predictions for the trucking industry in 2023. Among these predictions is the importance of driver preparedness and management changes in the transition to electric vehicles, the benefits of real-time data access for employees, and the role of technology takes in attracting and retaining talent. As the industry continues to evolve, these trends will be key to success in the coming years.

Successful fleet electrification will rely on driver buy-in and preparedness.

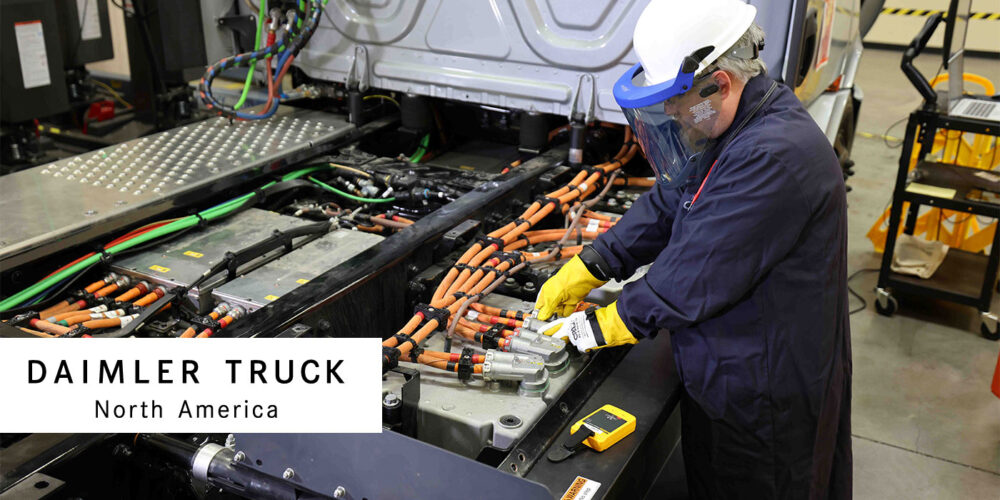

Despite regulatory incentives and reporting requirements for carbon emissions, we’ve yet to reach an inflection point when it comes to commercial fleet electrification. That said, preparedness remains critical as we get closer to this point. Common considerations for many organizations right now include detailed emissions reporting, suitability assessments to determine which vehicles should be transitioned to electric, and charging infrastructure placement. But one of the most overlooked areas of investment for any company looking to convert to electric vehicles is driver preparedness, safety, and change management.

Any shift to EVs will have a significant impact on the daily operations and infrastructure of drivers operating these vehicles. With this in mind, companies prioritizing fleet electrification in 2023 should secure driver buy-in early and have a change management plan in place, complete with the right training and coaching for how to manage these vehicles. Managers need to be thinking about the best practices and driver behaviors that might need to shift when operating EVs – for example, driving to best conserve battery charge, the best times and locations to charge, optimized routes for battery management, and more.

Jeff Hausman, chief product officer, Samsara

Real-time data made directly accessible to employees will provide a competitive advantage.

The macroeconomic environment and unique challenges our customers face (e.g. fuel costs, tight labor markets, supply chain pressure) will remain top of mind heading into 2023. It’s become paramount that organizations treat these problems as data problems and enable individual employees with the right information at the right time.

As operations become more connected, a proliferation of data will continue across industries such as trucking, construction, and manufacturing. In addition, there will be an increased importance on data that’s made easily accessible to individual employees on the front line. With real-time insights, alerts, and reports made available at their fingertips, these employees can make data-driven decisions and accelerate time to action. Companies that take this approach will gain a competitive advantage when it comes to operational efficiency, employee retention, and more.

Hausman

Career pathing and technology for professional drivers will help organizations win the talent war.

Instead of letting decades of wisdom walk out, organizations will carve new career paths for drivers who no longer desire to be behind the wheel. For example, rather than retiring, older drivers will take on training roles, bringing increased value to organizations and accelerating the time it takes for new drivers to learn the ropes. Using technology solutions in their day-to-day will also make the position more attractive to a younger, digital-native cohort who will help solve the ongoing driver shortage. Organizations that show they’re invested in career pathing and providing a modern and safer experience through technology will be the best at attracting and retaining drivers.

Sarah Patterson, chief marketing officer, Samsara

Data insights make always-on learning and personalized training a reality.

We’re living in an era of personalization. From recommendations on shows we watch to ads we’re served up online, we expect a custom experience, and training should be no different. The digital transformation of physical operations has unlocked the ability for organizations to provide personalized coaching to drivers and employees through insights gleaned from AI and data. These real-time insights will help organizations move past run-of-the-mill training sessions to a customized approach that gives employees tailored trainings customized to their specific learning needs. It will also open the door for leaders to celebrate and deliver the much-deserved recognition they want.

Patterson