Motor carriers can choose from many technologies to make their operation more efficient, profitable and safe. The bad news is many require significant costs before paying a return. The good news is that when it comes to weigh station bypassing, a small investment can pay quick and significant dividends.

And when you consider that PrePass offers more features than any other weigh station bypass service provider, then the benefits become even greater. Here are six important benefits your trucking operation can receive with PrePass.

Keep drivers driving on time

Delays in your trip or not moving freight create an opportunity cost to your business. According to the American Transportation Research Institute, these challenges run you about $65 per hour. In addition to this cost, the job of truck driving is more stressful than ever. Hours of service, lack of available truck parking and long detention times at shippers and receivers create daily uncertainties. As a result, drivers often have to make decisions on the fly. Even a 10-minute delay or a 30-minute inspection can cause a driver to be late for an appointment or force a rest break in a location they did not plan to stop. Bypassing weigh stations not only helps drivers be more productive, it reduces stress. And anything that helps reduce stress benefits drivers.

Save fuel and money

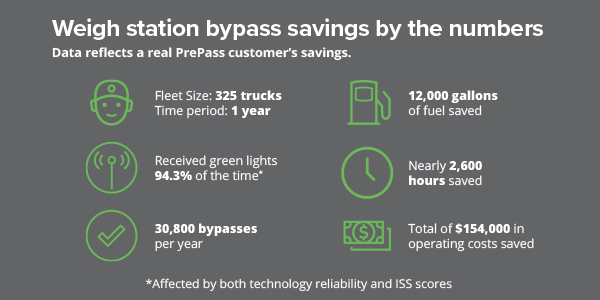

Fuel is one of the largest expenses for any motor carrier, so it’s always important to find ways to save on fuel costs, especially idling. According to the FMCSA, bypassing a weigh station saves on average $8.68, including half a gallon of fuel. Motor carriers realize these savings because their trucks bypass weigh stations, and maintain highway speeds. They don’t spend time idling and burning fuel at these facilities. Bypassing also saves carriers money by reducing wear and tear on truck brakes, tires and other truck equipment. And less wear and tear means lower maintenance and equipment costs.

Secure more business from shippers

Independent research from the University of Arkansas’ Department of Supply Chain Management confirms that the adoption of bypass technology by a motor carrier increases the likelihood of their selection by shippers due to eco-friendly practices. Since PrePass started compiling bypass data in 1997, PrePass documented reductions in truck-related emissions at weigh stations of more than 843,864 metric tons. That’s the equivalent of removing nearly 150,511 automobiles from the road! In fact, PrePass is the only bypass provider with a U.S. Environmental Protection Agency SmartWay affiliation, which encourages businesses to manage logistics in environmentally responsible ways.

Reduce truck crash risk

Any time a truck has to slow down or stop, crash risk increases. With weigh station bypassing, you reduce crash risk at weigh facilities because there is no slowing down or merging back into traffic. And when you add PrePass electronic toll payment services, you reduce crash risk even more. Figures from the Port Authority of New York and New Jersey show that vehicle crashes at its toll facilities fell by 57% over a five-year period following the implementation of cashless tolling and other improvements. When you reduce crash risk you reduce the chances that freight movement will be delayed. Also, fewer crashes can translate into lower insurance premiums.

Improve driver retention and recruiting

There’s an old saying in trucking. “If the wheels aren’t turning, you’re not earning.” For drivers paid by the mile, sitting in a weigh station can be frustrating. Weigh station bypass helps drivers maximize their earnings by keeping the wheels on their trucks moving. Bypassing weigh stations and avoiding delays makes happier drivers. And happier drivers stay with companies longer. In fact, a PrePass customer survey found that providing a bypass service is one of the top three driver benefits motor carriers can offer. And when it comes to recruiting, weigh station bypassing tells drivers you invest in technologies that make their jobs easier. Plus, when you add toll payment services to weigh station bypassing (something only PrePass can do), drivers save even more time not having to stop at toll booths. At the same time, fleets benefit from consolidated billing, toll discounts and easy toll dispute resolution.

Improve safety scores

PrePass is the only weigh station bypass service provider that offers easy, actionable data to carriers. This allows you to monitor your overall safety performance all the way down to the results of each individual law enforcement inspection. PrePass INFORM Safety software is available at no charge with the PrePass weigh station bypass service. And with easy visibility into the anatomy of your fleet’s inspection history, it gives you priceless information to help keep safety scores positive and find areas for improvement.

Weigh station bypassing delivers many benefits. But when it comes to selecting a service, only PrePass offers more than any other provider. With an extensive coast-to-coast network of weigh station bypass locations, PrePass offers the most choices in bypass technology that best suit your trucking operation, with either a transponder or the PrePass app, which includes real time safety ALERTS. Only PrePass offers both weigh station bypass and integrated electronic toll payment services with exclusive access to valuable software providing actionable inspection and tolling data. And with PrePass you have the peace-of-mind in using the only bypass service developed, owned and operated in the United States of America. It’s easy to see why PrePass is the best choice for saving you time and money every day.

This article was sponsored by PrePass. For more information, contact PrePass today at prepass.com/contact or (800) 773-7277 option #2