It’s a lot like déjà vu. For technicians who are fortunate enough to maintain a fleet of similarly-equipped vehicles, it comes as no surprise when they see the same fault codes and failures occurring on those vehicles.

Typically, there are a limited number of potential codes that ever set, even though some vehicle systems have the capability of setting hundreds of different fault codes. On one hand, having a limited quantity of recurring problems is good news, as this enables the technician to quickly gain an understanding of what fails frequently and how to correct the problem.

On the other hand, a downside may rear its ugly head. What in the world could be the downside to recognizing a common problem area and knowing how to fix it? The answer is over-familiarity — a presumed understanding that a particular problem is always the result of a specific set of circumstances.

The danger of diagnostic assumptions

Let’s take a look at how a diagnostic assumption can lead to a misdiagnosis and result in increased costs and downtime.

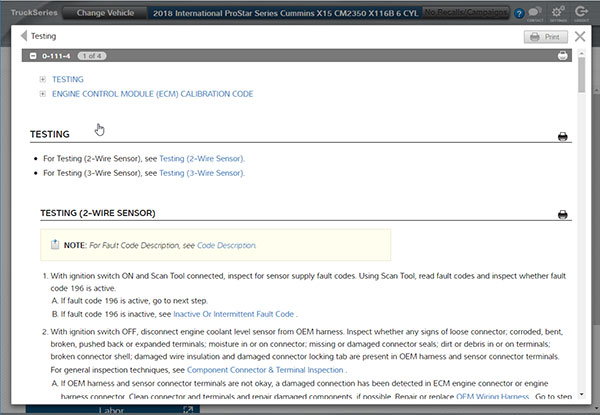

There is no question that being familiar with a fault code—both the cause and correction—can be a great timesaver for the technician. After all, some diagnostic procedures can take a lot of time and effort as the technician works through the diagnostic steps to systematically eliminate potential issues. By knowing where the fault generally occurs, the technician can go directly there without going through all the steps that lead to that problem point. But, this can be risky.

Unfortunately, there are times when fixing the assumed problem does not correct the actual issue on that particular vehicle. Then what? Labor and parts have been expended without fixing the problem. At this point, the tech starts working through the step-by-step diagnostic procedure, and the downtime clock keeps on ticking.

Another drawback to jumping to conclusions with diagnostics is that while the repair may correct the problem, the cause of the problem may be completely overlooked. A hypothetical example: When fault code XYZ sets, replacing the sensor corrects the fault code setting—but what is missed is why the sensor failed. Are the wires damaged by heat creating too much resistance? Is there excessive heat on the sensor? Does moisture get in the connector, causing corrosion which gets temporarily cleaned off with the new sensor?

There is no doubt that knowing failure patterns and the typical fix can provide a great head start in diagnosing a problem. This is especially true if the problem spot is not easily determined. Nevertheless, it is important to not simply abandon proper diagnostic procedures by jumping to a conclusion based solely on past experience, gut feeling or advice.

There may be many reasons why a failure occurred. Making the effort to better understand the “why” behind the failure can be more crucial than determining what failed. Without addressing the “why,” the “what” may very well turn into that familiarity paradigm where we keep replacing the same part over and over again. It’s a lot like déjà vu.

Additional tips for repair and maintenance of Class 4-8 trucks may be found in the Mitchell 1 ShopConnection Truck blog.