That’s one of the questions we asked ourselves as we dove into our second edition of the State of Heavy-Duty Repair. Our goal was to provide a deep dive into the industry, and to do this we surveyed hundreds of shop owners, fleet managers, technicians, and others across the United States and Canada.

We think the entire report is fascinating (yes, we’re a little biased), but wefound the data we collected about technician salaries particularly important in light of the economy and the ongoing tech shortage.

We took some of our findings in this area and fused them with up-to-date national statistics to provide a comprehensive look into the earning potential of diesel techs. We hope anyone can find this article useful—from the kid who thinks semis look kind of cool to the longtime tech considering asking for a raise.

How Much Do Diesel Techs Earn?

Let’s get the big question out of the way: how much can you make?

As in other industries, a lot of factors end up contributing to your overall salary. Experience and excelling at the job are definitely at the top of the list. But as far as actual hard numbers go, the Bureau of Labor Statistics reports the median annual heavy-duty diesel mechanic salary is $48,690, which works out to about $23.41 per hour.

Keep in mind those numbers are simply the middle of the pay scale. Some heavy-duty techs make as much as $72,000 to $93,000 per year.

On paper, a salary might sound like a better deal than an hourly wage, but it’s going to come down to how busy the shop is. Salaried mechanics are exempt from overtime pay in some circumstances. That means salaried techs in an extremely busy shop can end up working for much less than those who take an hourly wage and work typical hours.

Some shops might calculate your paycheck based on how many hours you actually spend working on trucks in any given pay period, rather than hours you’re clocked in (and possibly waiting for work).

More and more shops are implementing incentivized pay structures. They pay techs an hourly wage plus bonuses for high efficiency. If you can multitask, dropping oil on one truck while replacing the brakes on another one, for example, hourly-plus-bonuses can be lucrative.

Your Location Impacts Your Salary

Where you end up working can affect how much you make as a diesel tech—you’ll earn more in some states than others. During our research, we determined that the highest average hourly rate for heavy-duty techs tends to be in the Southeast—techs there earn an average of $31.61 per hour. The runner-up is the Western states in general, at $30.42.

We also took a look at monthly tech salaries by region. Leading the way, once again, was the West; techs there earn, on average, $6,023 a month. The Midwest followed with averages of $5,743 per month, with the Southwest clocking in third at $4,297 per month. The Northeast brought up the rear, with its techs averaging $3,000 per month.

Want to narrow it down even more? ZipRecruiter has compiled a list of the highest-paying states for diesel techs in 2022. Here are the top five:

- Massachusetts

- Hawaii

- Connecticut

- Tennessee

- Minnesota

While looking at the list above and comparing it to our regional data, you might notice a slight discrepancy—Massachusetts is apparently the top-paying state for techs, yet the Northeast on average pays the lowest monthly salary. Just remember that the numbers paint a picture together; other states around Massachusetts may have far lower pay rates, which pulls down the overall average.

Technician Shortage & Salaries

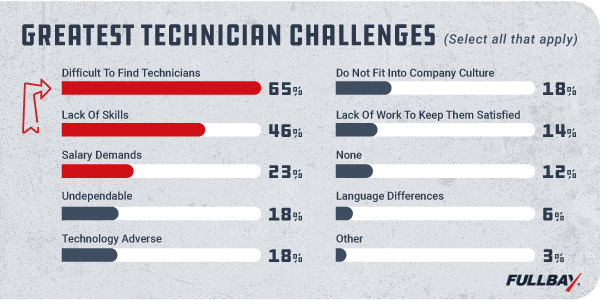

Something else to keep in mind is the ongoing technician shortage. Sixty-five percent of the shops we talked to told us their biggest difficulty was finding techs—any techs! There were other, smaller challenges like lack of skills (46%) and undependable (18%), but clearly the biggest challenge remains locating people to do the work at all.

The difficulty and expense associated with finding new technicians has started translating to shop owners realizing they need to work harder to keep the techs they already have. The easiest way to do this is through a good old-fashioned pay raise.

“I am fairly confident that those shops [that did not increase tech wages in 2021] saw an increase in turnover and a decrease in both efficiency and recruitment capabilities,” says Aaron Picozzi, President of American Diesel Training Centers.

It does seem like a lot of shops “get” it—the data shows us that in 2021, more than 73% of the shops we surveyed did provide a wage increase. The size of the increase ranged from $1 to $25, but the average jump was $13.88—pretty substantial.

It’s Not All Big Rigs

If you work in a dealership, for a fleet, or in a shop that specializes in semis, you’ll be doing a lot of work on Class 7 and 8 vehicles. However, you can get training to branch out and specialize in working on other types of large equipment. Plus, being able to service less common equipment often means commanding a higher salary.

Farm and road construction equipment are just two examples of diesel tech specialty areas. Cranes, bulldozers, tractors, harvesters, and even irrigation gear are some of the types of equipment you might work on for farmers or road crews. If you have an interest in boats, you might want to get a certification in yachts, ships, and marine equipment.

For instance, you could work for boat owners, private companies, or even the government, repairing and maintaining all sizes of vessels. You could also find work as a mechanic for a commercial fishing fleet keeping their boats running.

By the way, don’t forget aircraft! You can get certified to work on airplanes and avionics equipment and wind up working at an airport, for the government, or even start your own fixed-base operator service.

Wanna Go Mobile?

Many techs earn their heavy-duty diesel mechanic salary clocking in to work at a shop all day. However, some shops offer mobile service, sending techs directly to the customer.

If you land a position as a mobile mechanic, you’ll be doing a tech’s job…while working out of the back of your truck wherever the work happens to be! That could mean meeting a customer roadside to do a repair or going to a fleet yard to perform multiple PMs. Both scenarios save the customer time, making mobile mechanics a valuable option for shops and customers.

Just keep in mind that mobile techs often end up working outside regular business hours—sometimes way outside regular business hours! After all, roadside breakdowns don’t always happen between 9 a.m. and 5 p.m.

Something we’ve learned during our years in diesel is that customers love it when a tech can come in after hours to do oil changes and other preventive maintenance. They’re getting necessary work done without downing a vehicle during what might otherwise be a busy workday.

The More You Learn, the More You’ll Earn

We mentioned that it’s possible to start at the bottom and learn the heavy-duty repair business on the job. If you’re just starting out, understand that training an inexperienced tech takes time, and time is money. Managers and owners are willing to pay a rate for experienced techs because #1, they know what they’re doing and #2, the shop won’t have to spend time (and money) training them.

Whatever experience you already have, it’s never a bad idea to get more. Continuing education for diesel techs is where you’ll find the specialty certification programs we mentioned above. Any areas you specialize in beyond the basics like engines and fuel, electrical, and brake systems put you in higher demand and increase your earning potential.

Job Security

The job outlook for skilled heavy-duty techs is good, with 8% growth expected through 2030. That’s because not only is the shipping industry expected to grow, but diesel vehicles, including light trucks and passenger cars, are increasing in popularity. More diesel equipment on the road means a growing demand for mechanics…which is currently running up against the aforementioned shortage. We’ve already discussed the positive impact the shortage is having on the salaries of those already employed; we’ll add here that shops will need to offer higher salaries in general just to attract talent.

Whew! That was a lot of data. Do you want to see what else we learned? You can get your very own copy of the State of Heavy-Duty Repair from Fullbay. Click here to download your copy of the report!