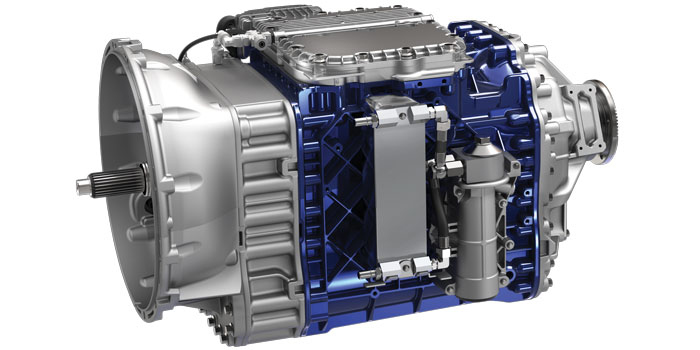

New technology requires a willingness to do something different, to learn something—new training and new maintenance practices to tackle new problems. Consider automated manual transmissions (AMTs).

“Fleets have high expectations when an AMT needs repairing,” began Gary Pfister, manager of technical services for Eaton Corp. “They depend on the service facility to be well equipped with the troubleshooting and service manuals, diagnostic and service tools and parts to get the vehicle back on the road within 24 to 48 hours, but technician training is the most important factor.

“A service facility can be highly ineffective if the technician hasn’t received the proper training to be efficient in diagnoses and repair of the AMT.”

Let’s start with the basics. Pfister outlined three main AMT categories. You’ve already heard the first: technician training. The other two are vehicle system maintenance and service facility capability.

“From a vehicle perspective, electrical system maintenance is by far the most important factor in making the transmission perform flawlessly during its lifecycle,” Pfister said. “As vehicles become more technologically advanced the electrical system plays a larger role in customer uptime.”

“Vibrations and abnormal noises don’t necessarily indicate a transmission issue,” Barton said, “but are warning signs that something has changed and should be checked.”

Donald Barton, Allison Transmission’s director of service engineering

He went on to explain that batteries, power and ground connections, and data link integrity are key components in allowing the transmission, engine, and other vehicle systems to work simultaneously to fulfill driver expectations.

When it comes to the third bullet point— service facility capability— you need to do your basic maintenance blocking and tackling, making sure you have the right tools, information and parts to service an AMT. And that brings us back to technician training, because you can have all those ducks in a row but you’d better make sure that your technicians know how to utilize them correctly.

“First-attempt repair success is critical in getting the vehicle back on the road in a timely manner,” Pfister said. “Nobody is a benefactor if the technician has to make numerous attempts to successfully repair the vehicle.”

Diagnosing an AMT issue: What’s it doing?

The driver will be the first one to know that there’s a problem with the AMT, but the problem is that the driver won’t know what the problem is. That’s your job. Start with having a conversation with the driver about his or her experience.

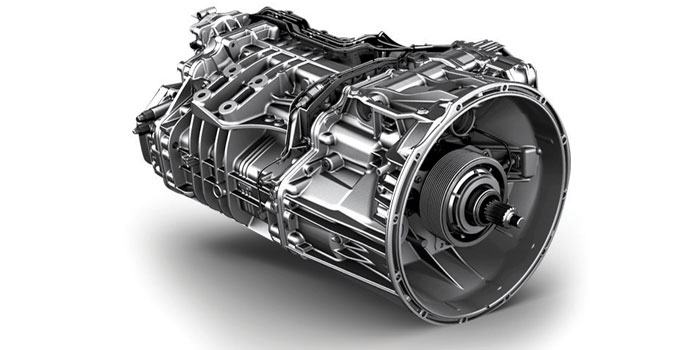

“The driver will experience hard shifting, noises or even fault codes,” said Jeffrey Burrow, manager of field quality support for Volvo Trucks North America. “If it’s shifting hard, that may be from air system contaminants in the clutch actuation valve. And fault codes can be read through telematics, system data analysis and/or reports from the dealer about a customer complaint.”

“Poor launch quality, inability to get into a gear, and/or missed or harsh shifts—when the driver experiences these conditions he or she may see a fault code displayed in the vehicle dash,” Eaton’s Pfister noted. “However, there may be vehicle system issues that do not display a fault code. In these cases, it is important for the driver to record the performance issue in as much detail as possible and report it to the fleet maintenance personnel for further diagnosis.”

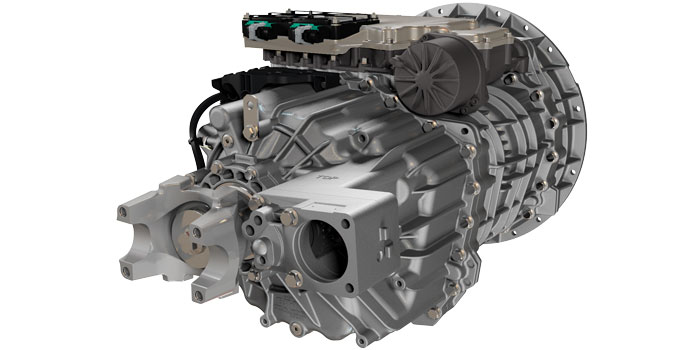

Brian Daniels, manager of powertrain and component products for Detroit, highlighted Detroit Connect Virtual Technician’s ability to provide insight to make informed decisions.

“Detroit Connect Virtual Technician provides guidance on how serious the fault code is,” he said, “as well as where, when and how to fix the issue so you can make informed maintenance decisions and get back on the road faster.”

Grinding gears

One of the biggest benefits of AMTs is that they reduce the maintenance bell curve, so overall you should see fewer transmission maintenance issues with AMTs vs. manual transmissions—specifically in clutch replacements.

“We see better life on the clutch for AMT than on the standard because of the transmission controlling the shifting and engagement and disengagement,” Volvo’s Burrow confirmed.

That said, AMT clutches still require maintenance. Pfister noted that AMT electronic systems have data recording capabilities that can log certain parameters that will indicate an abusive situation.

“Using the proper diagnostic service tool this data can be extracted and reviewed,” he said. “Many fleets pull these data extractions on an annual basis to understand the AMT’s performance and driver’s habits. There can also be physical signs of adverse operation. Premature part failures can be analyzed using failure analysis tools to understand if it is a driver-related issue.”

“There are many features built into AMTs that disallow the driver from abusing the transmission to the point of a premature failure,” Eaton’s Pfister said. “Needless to say, premature failures can still happen if the driver is persistent in operating the vehicle outside of the defined guidelines in the operator’s guide.”

“If a driver holds the truck on a grade with the throttle,” Volvo Trucks’ Burrow explained, “it will damage the clutch and cause shifting issues. A fault code will be set in the transmission TECU and will show up as excessive clutch wear.”

You might not have to keep clutch stock, but you’ll want to have the order ready when the truck is scheduled to come in for its transmission PM. Both Detroit and Volvo noted that they offer two clutch specs.

In Detroit’s case, the DT12 transmission requires a dual plate clutch for GCW greater than 105,000 lbs. and a single plate clutch is available for GCW less than 105,000 lbs. “A customer has the option to spec a dual plate clutch even if their GCW is less than 105,000 at the time their truck is built but cannot upgrade later,” Daniels noted.

The automatic difference

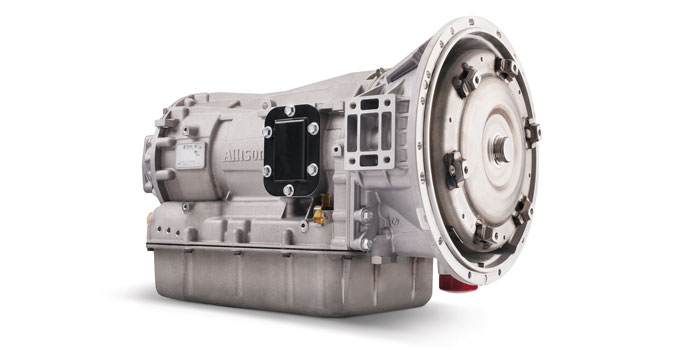

If you’re maintaining hard-work, heavy-duty vocational workhorses, chances are that you see a lot of Allison transmissions roll in and out of your shop. (Allison owns a healthy chunk of that market.) It’s important to note that an automatic transmission is different from an automated manual transmission. The differentiator is in how Allison handles torque.

When you shift a manual or automated manual transmission and engage the clutch, the engine torque is interrupted and that power isn’t getting transferred down the drivetrain to the wheels. In a fully automatic transmission, like those offered by Allison, the torque converter allows you to shift gears without interrupting the torque going from the engine to the wheels.

In terms of maintenance, however, many of the big bullet points are the same compared with AMTs. Changing the transmission oil and filter at the recommended intervals is your first line of defense.

“Much of the time, transmission issues can be maintenance related,” said Donald Barton, Allison Transmission’s director of service engineering, on-highway products. “For example, if the oil wasn’t changed on time, or the wrong oil levels are maintained, or there’s something vehicle maintenance related like a universal joint is worn out.”

In addition to the Check Transmission light that will indicate a service need, drivers may notice vibrations or abnormal noises indicating the vehicle should be taken in for service.

“Vibrations and abnormal noises don’t necessarily indicate a transmission issue,” Barton said, “but are warning signs that something has changed and should be checked.”

When it comes to automatic transmission operation, Barton said that Allison transmissions are designed with interlock and safety settings to prevent a driver from adversely impacting the equipment. That said, if there’s a way, some drivers will find it.

“One example of a way that a driver could hurt the transmission is by getting the wheels stuck somewhere and putting the truck in gear and running the engine at full throttle. That will overheat and deteriorate the fluid,” Barton said. “Additionally, if a vehicle is towed without lifting or disconnecting the drive axles, the transmission will spin without any lubrication, causing abnormal wear.”

Transmission oil changes… or similarities

The more things change, the more they stay the same. Across most OEMs, it doesn’t matter if you have an AMT or a manual transmission, the transmission oil and filter intervals remain the same: 500,000 miles. Some transmission OEMs add the stipulation “or 60 months” so it’s imperative, as always, that you know your specific manufacturer’s transmission oil and filter recommendations. But understand that it’s not the age, it’s the mileage.