In today’s trucks, there seem to be fault codes available for virtually every monitored system. Because these systems interact with each other, it’s not uncommon to see multiple codes being set.

In many cases, diagnostic procedures will indicate whether additional fault codes may be set that share circuitry or depend on the actions of another system. As a rule, we expect the diagnostic procedure to lead us down the most efficient path to identifying and resolving the immediate problem, as well as the root cause of a fault code. Repairing a damaged circuit is likely only a temporary fix if we don’t determine what caused the damage in the first place.

Diagnostic procedures usually help us to dot our i’s and cross our t’s when we take the time to follow them. Having a diagnostic path to follow is a great help, even though it may appear a bit laborious at times, as some steps just sound pointless.

For instance, why do I need to check the battery voltage when the voltage at the component is either clearly within specification or it is not? Well, perhaps some other system up the line to the circuit we are testing needs battery voltage to function. So, step-by-step diagnostic procedures can be a pain but generally help us to resolve concerns with the least amount of effort.

What do you do when the problem we are confronted with does not have any published diagnostics—hope it gets assigned to another technician? Let’s say the concern ends up in our bay after all. What we can do is have a plan. And that plan can include these five steps to help lead you to an accurate diagnosis.

Read more maintenance and service tips from Jake Schell here.

- First, gain information about when and how the problem occurs. This is especially critical with intermittent issues.

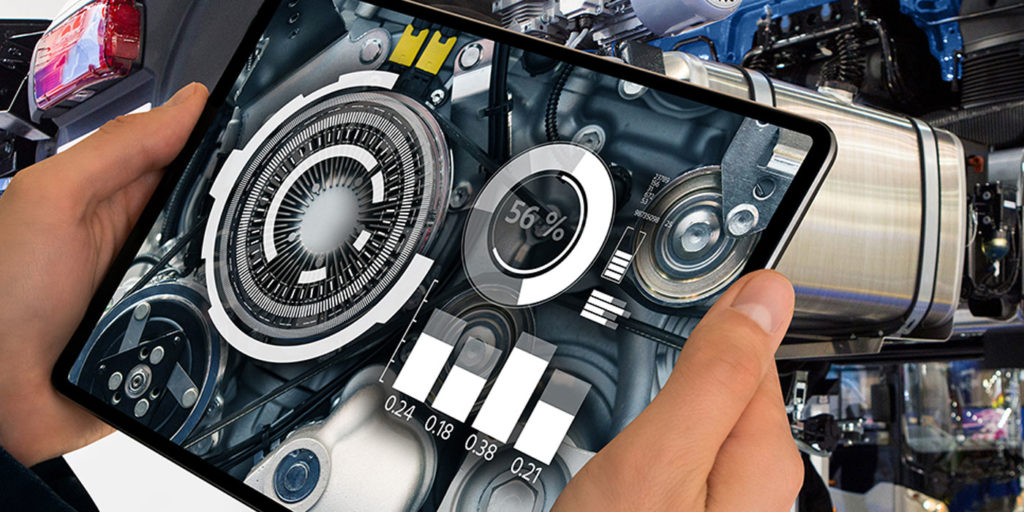

- Learn as much as possible about a system through the service information description and operation. TruckSeries from Mitchell 1 is an example of a resource for this type of truck repair information.

- Review the system wiring diagrams for circuits in the system as well as those circuits that tie in through shared power and ground connections. When possible, note harness routings to see potential movement or pinch points where damage may occur during operation. Also, be aware that splices tucked away inside a harness can be difficult to spot.

- Check for any heat sources near the circuit that may not be properly guarded or just routed too closely. In addition, missing and damaged water shields could be allowing water to enter connections and subsequent short-circuits.

- Sometimes it may be necessary to systematically check a circuit. When that need arises, put together a checklist to indicate that a section of a circuit was inspected for an open, short to ground, short to power, or short to another circuit.

Going to all this effort to identify a problem takes time and patience. Yet, these diagnostic skills pay off in the long run and make a technician all that much more valuable to a fleet or service provider. And of course, it’s always rewarding to be able to track down and fix problems that go beyond the everyday fault codes and repairs coming through a shop.