Trailer service pop quiz: Do you consider inspections “maintenance”?

Answer: Maybe you should, according to Greg Dvorchak, Engineering Supervisor – Brake and Wheel-End Division, Hendrickson.

“Inspection is maintenance,” says Dvorchak. From his perspective, service needs and preventive maintenance are two different things. Preventive maintenance is done to extend intervals between service or avoid unplanned wheel-end service. “There is no such thing as a maintenance-free wheel-end,” says Dvorchak. “If you’re doing an inspection–even down to the driver’s pre-trip inspection–that’s effectively preventive maintenance.”

Here are his wheel-end maintenance tips that go beyond the daily inspections:

• Every month: Look at the hubcap and make sure it’s not cracked or damaged. Make sure there’s no leaking around the hubcap gasket. On the hub’s wheel seal side, look and make sure there’s no lube leaking out of that area as well.

• Every three months: Inspect the wheel-end itself. Hendrickson recommends lifting the trailer and spinning the wheel-end to look for quiet and smooth rotation.

The challenge comes when something is identified in the preventive maintenance and inspection process, which may require deeper investigation and service to the wheel-end. It is important to use the correct components and procedures when re-assembling the wheel-end to avoid future complications.

“From an engineering standpoint, we’d love it if you never had to take that hubcap off. The minute you do, now you’re on to the potential risks, or my unofficial things-that-can-go-wrong list,” Dvorchak said. “The minute you take the hubcap off, you are subject to introducing contamination to the wheel-end, something as simple as water or as harsh as metal, rust or anything that can get in and interfere with the proper operation of the bearings.”

“Setting the wheel-end play is something that our tech service team trains our customers on how to do properly,” he said, “because if you go too far one way or the other, or it’s too tight or too loose, you’re going to potentially have bearing life that’s not what you expected it to be.”

That’s just one of the components that can lead to unplanned service as a result of improper wheel-end maintenance. As Dvorchak alluded to, your supplier of choice should be the go-to source for wheel-end service information. He noted that Hendrickson works regularly with fleets to ensure that wheel-ends are properly inspected and serviced.

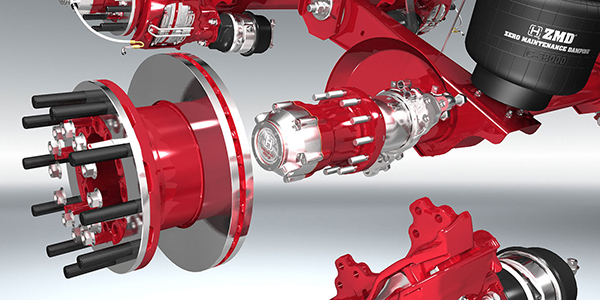

Spec’ing the right equipment on the front end can also help reduce unplanned wheel-end maintenance. Hendrickson HXL7® Extended-Life Wheel-End with Outboard Mounted Rotor is a new technology for air disc brake wheel-ends that helps increase uptime and improves serviceability. The Outboard Mounted Rotor option allows for rotor servicing without disturbing the hubcap and wheel-end.

“The major benefit is if you have to service the rotor, the rotor comes off by itself–you do not disturb the hubcap, the hub, or the bearings. The primary benefit is that you maintain the integrity of the bearings and the wheel-end.” Dvorchak explained. “From a practical standpoint, for a technician, if you’ve had to change rotors on an inboard-mounted wheel, I can see those guys clapping for only having to take the rotor itself off when servicing a rotor.”

Click here for more information about Hendrickson’s HXL7 with Outboard Mounted Rotor.