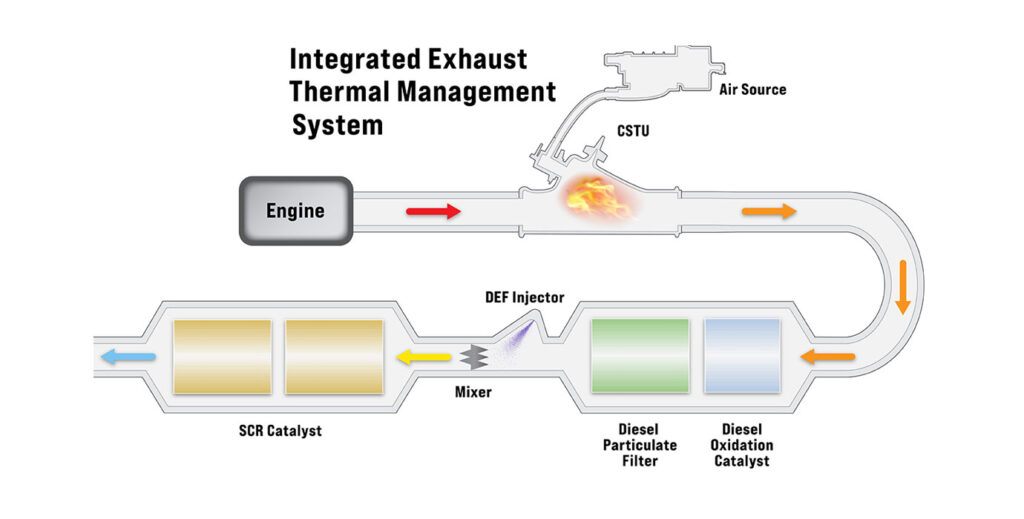

Eaton and Tenneco have entered a joint development agreement between Eaton’s vehicle group and Tenneco’s clean air business group to produce an integrated exhaust thermal management system that will enable commercial truck and light vehicle manufacturers to meet upcoming emissions regulations.

Across the globe, emission standards are tightening for vehicle manufacturers. In Europe, the next stage of emissions standards, known as Euro 7 (for light-duty vehicles) and Euro VII (for heavy-duty), are targeted for introduction in 2025. The California Air Resources Board (CARB) and the U.S. Environmental Protection Agency (EPA) have similar actions planned for 2024 and 2027, respectively. Collectively, these new regulations will reduce tailpipe NOx limits by 90%, Eaton says.

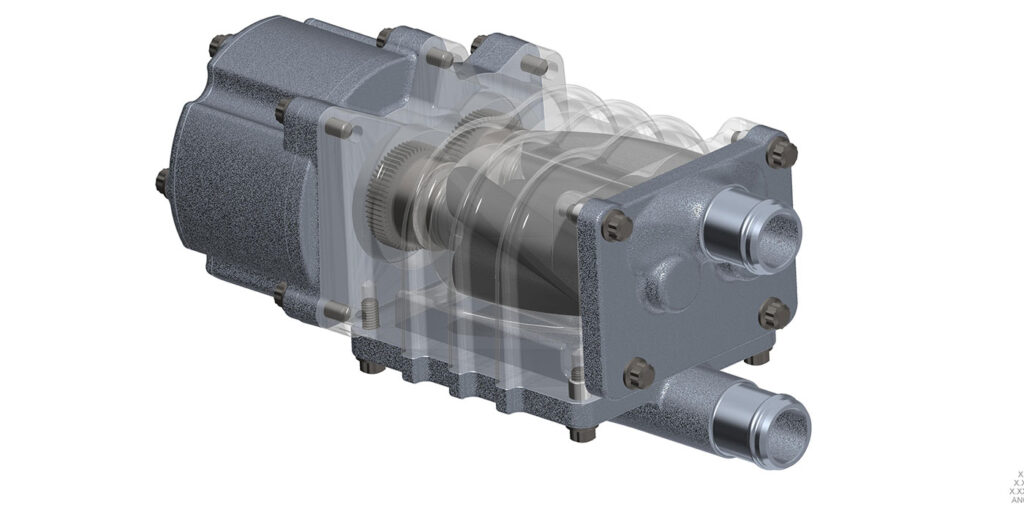

Under terms of the agreement, Tenneco’s Cold Start Thermal Unit (CSTU) will be combined with Eaton’s TVS blower technology. The integrated exhaust thermal management system will provide heat directly to the vehicle’s aftertreatment system, which is essential for reducing harmful exhaust emissions, the companies say. Upon heating the SCR catalyst to approximately 200 to 250 degrees Celsius, the aftertreatment system can efficiently convert NOx into clean emissions (e.g., nitrogen and water particles) upon exiting the SCR catalyst. Eaton’s electrically-driven TVS Roots blower allows the airflow to be efficiently and precisely controlled so the CSTU can maintain optimal aftertreatment temperatures.

Development activities will take place at Tenneco’s technical center in Edenkoben, Germany, and Eaton’s technical center in Marshall, Michigan. The integrated exhaust thermal management system is anticipated to be ready for start of production in 2025 to support regulatory timing, the companies say.