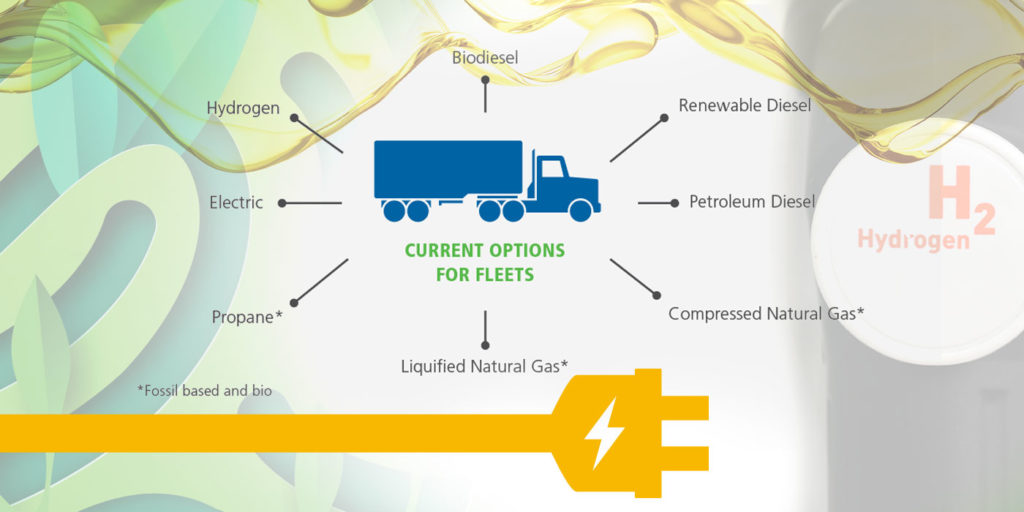

As the evolution toward running on more than a single fuel source continues, fleets turning to alternative fuels are spurred by growing environmental regulations and sustainability plans. That’s why, rather than thinking about a straight replacement to diesel, fleets should adopt an integrated energy management (IEM) approach—a comprehensive strategy that considers all available fuel sources and adopts any and all options that best meet their needs.

An IEM approach allows for a transition away from fossil fuels while taking into account the market readiness and affordability of various alternatives. This helps meet both short- and long-term business objectives and incorporates more types of cleaner energy sources to help achieve sustainability goals. Diversifying energy sources also reduces the risk of being dependent on any one fuel, which is smart in our ever-changing world.

To get the ball rolling on an IEM approach for your fleet, it’s best to start at the beginning, as they say. Research the various fuel options available to you — that could mean online research, talking to your supplier or asking other fleet managers what they use. Perhaps you need to test some of them out as well, to know if the conditions your vehicles work in will be conducive and to understand any equipment changes that may be required.

Take your drivers’ and technicians’ opinions into account as well — after all, they’re the ones experiencing the results every day. Gather performance and emissions data the best you can and see how it compares to what you’re hearing from your team. Consider who else has a stake in your energy sources (for example, a municipal fleet may have constituents or a city council to keep in mind). Once you’ve done this prep work, you’re ready to put an approach into place.

So, what does integrated energy management look like in practice? Let’s use a fleet with 100 vehicles as an example. Say they can afford to convert five trucks to electric, and performance-wise it makes sense for those to be the ones making short-range hauls. They also buy five compressed natural gas trucks. Rather than keeping the other 90 on petroleum diesel, the fleet uses drop-in, cost-effective fuels like biodiesel blends and, to stretch its hard-to-get renewable diesel supply, a blend of renewable diesel and biodiesel. Now 100% of the fleet is running on lower-carbon fuels while keeping budgetary and performance factors in mind. This is integrated energy management.

If you’d like to learn more about the IEM concept, I’d be happy to chat.

Steve Klein is senior manager of marketing at Renewable Energy Group, a biodiesel and renewable diesel producer. He can be reached at [email protected]. You can read more from the Renewable Energy Group by clicking here.