If there is oil in a heavy duty truck’s coolant, it always means there’s a serious underlying problem. If repairs are made quickly, major damage can be prevented. Your employees should be inspecting your trucks on a regular schedule for signs of oil in the coolant. They should also be looking for signs of coolant in the engine oil or transmission fluid.

Often, junior technicians are responsible for routine maintenance. Don’t assume that they know what to look for. You need to train them to look for the following symptoms:

What to Look For:

Oil in the Coolant – The first symptom of oil in the coolant is an oily sheen on top of the coolant. This will be visible after pulling the radiator cap, or you may see it in the overflow reservoir. If the problem is more advanced, a brownish sludge will be visible at the top of the radiator.

Transmission Fluid in the Coolant – Often, the first symptom of transmission fluid in the coolant is a swollen radiator cap seal. Also look for a pinkish brownish sludge at the top of the radiator.

Coolant in the Transmission Fluid – The coolant on the transmission dipstick should be pink. If there is a pinkish brownish sludge, coolant has entered the transmission.

Coolant in the Oil – If coolant enters the engine oil, the there are several visible signs. Look for sludge on the dipstick or underside of the fill cap (if the fill cap is on a valve cover). Another symptom is that the oil level is higher than it should be.

The best way to pinpoint the problem is to examine the three different parts that often cause oil/coolant contamination.

1. Oil Cooler

Most modern heavy duty trucks have an oil cooler. When the oil cooler fails, oil forces its way into the cooling system. Oil is under much higher pressure than coolant, so this is usually a “one way” leak.

2. Transmission Cooler

In most trucks with an automatic transmission, the transmission fluid is cooled by a transmission cooler. Sometimes the transmission cooler is integrated into the radiator. The wall separating the transmission cooler from the radiator can develop cracks. If this happens, the transmission fluid can get mixed into the coolant. This is a “two way” leak, so the technician needs to check the transmission for coolant too. Coolant can easily leak into the transmission fluid and severely damage the transmission.

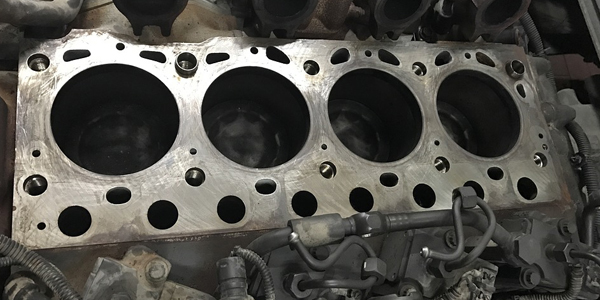

3. Head Gasket

A blown head gasket may cause the oil to leak into the cooling system. It can also cause the coolant to leak into the combustion chamber and burn. In some situations, coolant is forced into the oil, and ends up in the oil pan. A blown head gasket can be diagnosed with a compression test.

This article was sponsored by GMB North America, Inc. For more information, please visit our website at www.gmb.net