Hi! David here, and this week we’re on the road again, as Peterbilt invited us out to experience the all-new PACCAR TX-18 and TX-18 Pro automated transmissions at the Eaton Proving Grounds up in Marshall, Michigan. And they did this by letting me get behind the wheel of one of their heavy-duty trucks carrying a 140,000-pound load, to take it for a spin around their test track, which includes a 500-ft. hill at an 8% grade, and a 300-ft. hill at a 15% grade.

Click here to watch more of FE’s On the Road video series.

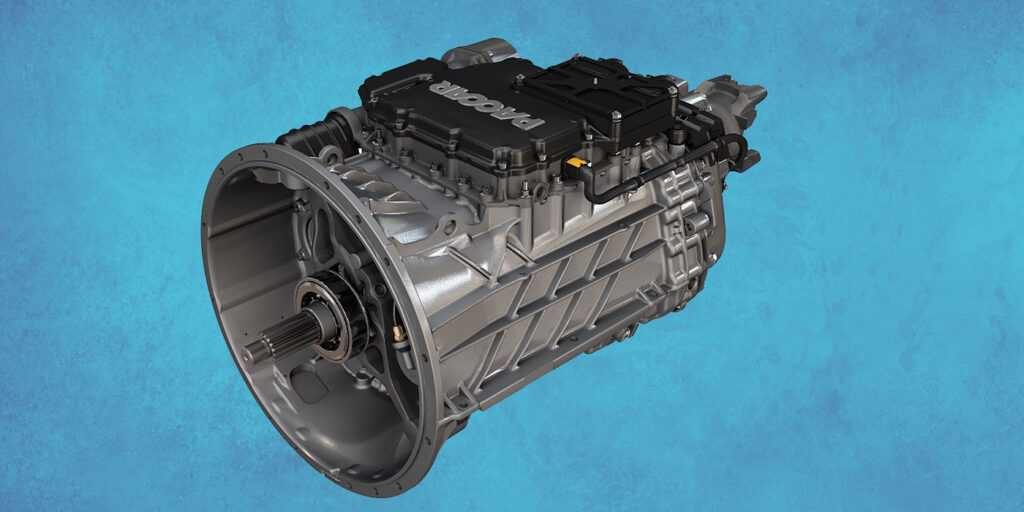

Now, a little background, the TX-18 is designed to work exclusively with the PACCAR MX-11 and MX-13 engines available in Peterbilt Models 567, 389 and 579, and the thought is that this transmission will just be a workhorse for vocational applications like heavy haul, dump truck, and cranes. Peterbilt says the combination of the TX-18 transmission and the MX engine provides up to 1,850 lb. ft of torque and is rated up to 140,000 pounds of gross combined vehicle weight rating.

The TX-18 is kind of the next step up from the PACCAR TX12 automated manual transmission that you’ll also find in the MX-11 and MX-13 engines, which is rated up to 110,000 pounds. So, if your trucks are hauling more than that, or if maybe you’re hauling 100 or 110,000 pounds but you’re in the mountains and you’re going up and down steep hills or maybe regularly sitting in traffic on a 10% grade, Peterbilt says the TX-18 is going to meet your needs.

Peterbilt had three trucks waiting for me – a 389 spec’d with the TX-12 carrying 80,000 lbs., a sleeper cab with the TX-18 carrying 80,000 lbs., and finally a day cab with the TX-18 Pro carrying 140,000 lbs. Each truck had the same MX-13, 510 HP engine.

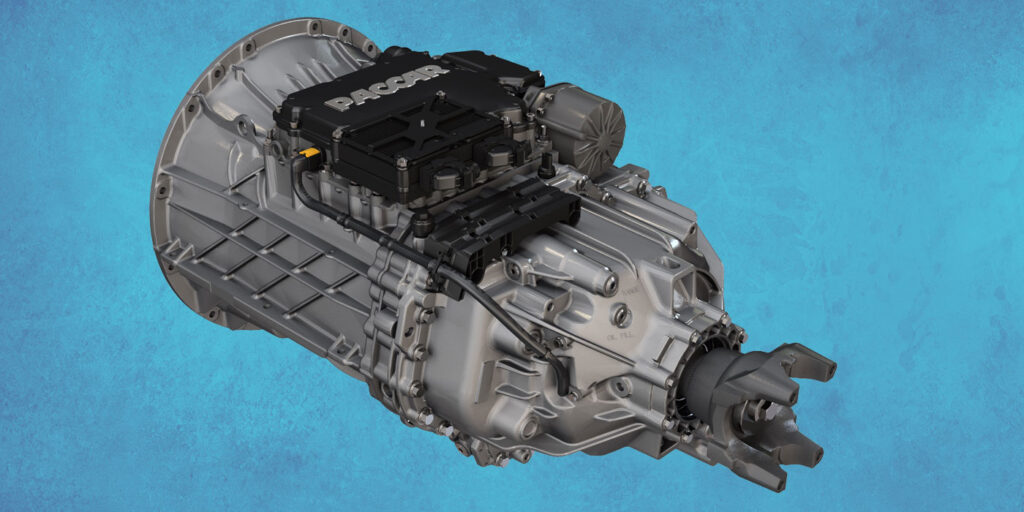

So, we’ve got the TX-18 and TX-18 Pro – what’s the difference? The base TX-18 variant is more suited toward on-highway, high performance with some mild vocational applications, while the TX-18 Pro is better suited for on- & off-highway high performance with both mild and vocational applications.

Getting technical, both variants are rated for 1,850 lb. ft of torque and up to 140,000 pounds GCWR, but the Pro model also features six reverse gears, an extreme duty clutch and is specifically calibrated to be able to handle off-highway performance. So, Peterbilt says the really heavy vocational applications, logging, or trucks running in an oil field, mining, things like that, the TX-18 Pro is probably going to be the direction you end up going. Just keep in mind that it’s going to depend on your fleet, and fleets should definitely talk to a dealer about the specifics if they’re interested in spec’ing this component.

The TX-18 comes standard with two PTO openings, one on the back of the transmission and one on the bottom, and combined Peterbilt says this is going to equal 160 HP. This transmission also offers a mobile PTO, so the driver can operate the PTO while driving. This might come in handy for a rock spreader, paint stripers, or a dump truck where you want to spread as you go.

The company says the TX-18 has a 47% reduction in parasitic losses and is 225 lbs. lighter than the previous vocational AMT iteration. And, although Peterbilt admits it’s hard to estimate fuel economy on trucks because there are so many applications, they estimate there’s about a 2% improvement over the previous AMT nonetheless. Going back to that parasitic loss improvement, Peterbilt says that because of the efficiency improvements in the build of the TX-18, you don’t need a transmission cooler below 110,000 lbs. Good news for the drivers, Peterbilt designed the TX-18 with 18 gears which means very small gear steps.

And, then we get to one of the features which I had a lot of fun with on the proving grounds 8% grade hill – urge to move. The Peterbilt engineers asked me to come to a stop in the middle of that hill as if I was emulating a traffic jam, and when I took my foot off the brake, the truck literally had this urge to move forward. Even with 140,000 lbs. behind me that urge to move feature didn’t struggle at all to continue creeping forward when I was ready for it to do so. And then, it calculates the angle and how much load you’re carrying and will select the best gear to make sure that you’re maintaining your speed as much as possible, even upshifting when it sees that you can go faster. It was really cool.

So, that was my experience with the PACCAR TX-18 and TX-18 Pro automated transmissions. Peterbilt says it’s available in July 2022, and they did clarify that the Eaton Ultrashift transmission will continue to be available for some time, but at some unknown point in the future they will be phasing that out.