STEMCO recently announced the next phase of RFID sensor-based BAT RF products that use automatic communication modes to collect and manage fleet information. According to the manufacturer, the BAT RF scalable automated sensor system allows fleet managers to capture real-time truck and trailer information, enabling them to improve productivity, enhance safety and security, and increase efficiency.

STEMCO recently announced the next phase of RFID sensor-based BAT RF products that use automatic communication modes to collect and manage fleet information. According to the manufacturer, the BAT RF scalable automated sensor system allows fleet managers to capture real-time truck and trailer information, enabling them to improve productivity, enhance safety and security, and increase efficiency.

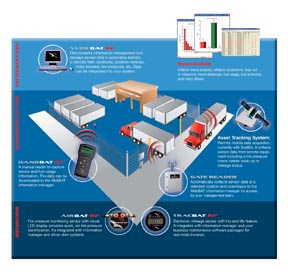

The BAT RF system incorporates sensors mounted to a vehicle that measure tire pressure, mileage and the asset’s identification. As vehicles enter a “wake-up” field, information is automatically communicated to a web-hosted application from each sensor, providing “at a glance” information on every piece of equipment in the fleet. WebBAT flags vehicles requiring attention so they can be dealt with immediately. Fleet information can be monitored real-time or reviewed as needed from easy to read reports that highlight the problem areas. Because the data resides on the Internet, it is available to the right users in the right location from anywhere, the company says.

BAT RF is a scalable system –– the sensors can be used alone in the simplest form or as a more complex business system depending on fleet size and customer needs. For example, the AirBAT tire pressure monitor provides warning lights on the wheel to indicate that a tire is under the fleet’s specified tire pressure limits. The person responsible for trip inspection can simply look for the flashing lights to determine what action if any, is needed. When the sensor is used in conjunction with the entire BAT RF system, information is captured automatically and can be managed by anyone with access to the Internet. Tire gauges are no longer needed, which eliminates inaccuracies and maintenance expense.

The TracBAT electronic hubodometer provides mileage collection and can be used to schedule maintenance by mileage activity rather than time. Each unit has a display for visual reading of the mileage. Since trailer usage varies widely from unit to unit, time-based systems cause some equipment to be serviced even when not required. Other more heavily utilized equipment may go without proper attention. Additionally, fuel mileage calculations are automated and accurate, the company says. Leasing fleets can automatically collect mileage data for billing and contract management.

The asset ID sensor can be used in conjunction with gate control to heighten security measures and prevent unapproved access. Fleet managers will know that the right trailer is coupled with the right tractor and driver to avoid mistakes and delayed shipments.

Several communication modes are available for the capture of information.

-

Fixed reader: positioned at the gate as vehicles enter and exit the yard or at a maintenance facility or at the fuel island

-

Asset tracking systems: a BAT RF interface module permits mobile data acquisition through established asset tracking systems, currently available with SkyBitz.

-

HandBAT – a manual reader used to capture sensor and fuel usage data.

All of these communication modes are interchangeable. Whatever the mode of communication, data received from the sensors is downloaded and stored on the WebBAT information manager in the fleet’s specific database.

The maker says the key to the BAT RF system is using this single collection point to monitor the fleet using real-time data as the information streams into the operation. Operations and maintenance personnel are able to use the information to quickly address maintenance issues without checking the entire fleet to determine which vehicle needs attention. This exception model allows the vehicle to identify itself thereby delivering real productivity improvements through labor savings, maintenance efficiency and expense reductions.

Because the system is designed in a modular fashion, future BAT RF sensors can easily be added and integrated into the fleet operating environment continuing to take advantage of the fleet’s investment. BAT RF products allow fleets to capture information, manage the operation and take action to improve productivity, fuel efficiency and safety. The BAT RF System by STEMCO provides the right information to the right person in the right form at the right time.

Refer to http://www.batrf.com for additional information. For more information about STEMCO, visit http://www.stemco.com.