The axle is a complementary part, working with both the powertrain and the suspension. It’s important to understand the relationship between these components and to make sure that your truck and trailer axles are operating in unison with the parts they complement.

So let’s go over the various parts that the axle intersects with, from the engine and transmission to the suspension to tires and brakes. We’ll look at what fleet managers need to know when spec’ing each of these parts to retain that necessary harmony.

…The powertrain

As a key part of the powertrain, the axle must be spec’d to work with the truck’s engine and transmission to maximize efficiency.

Or, to put it in more musical terms: “the engine, transmission, driveshaft and drive axle operate in harmony as a symphony orchestra of the vehicle.”

That’s Steve Slesinski, director of global product planning for Dana.

“However, if spec’d incorrectly, the result can be like a dysfunctional garage band,” Slesinski went on. “From determining engine horsepower and torque, to transmission type and axle ratio, properly spec’ing a drivetrain to a fleet’s intended use is what provides the desirable measure of vehicle performance while maintaining the right level of overall fuel efficiency. Regardless of vocation, the objective is always to provide the maximum vehicle reliability and performance.”

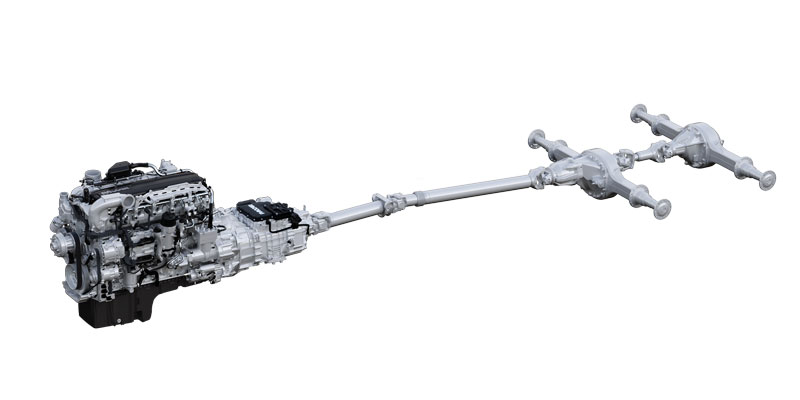

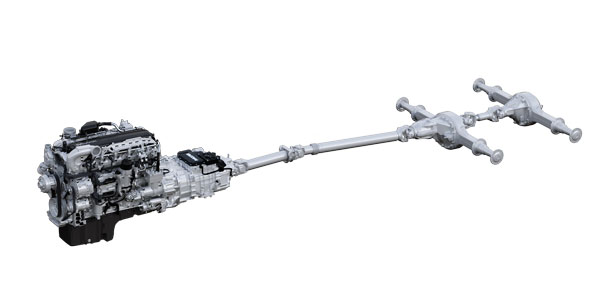

Many truck OEMs, including PACCAR, Detroit and Mack, are providing a fully integrated powertrain including an axle.

“PACCAR’s proprietary integrated powertrain, which includes the PACCAR MX engine, PACCAR Transmission, and PACCAR Axle, has had excellent reception in the marketplace with over-the-road fleets,” said Landon Sproull, PACCAR vice president. “Our design team and engineers created a powertrain that works seamlessly together for superior performance that delivers up to a 5% improvement in fuel savings, along with a 500-lb. weight savings compared to a non-PACCAR branded integrated powertrain. What’s more, our PACCAR Powertrain offers excellent serviceability since both the engine and transmission can be accessed by the same service tool.”

According to Roy Horton, Mack Trucks director of product strategy, highlights of Mack’s axles include: top-loaded axle carriers that greatly reduce driveline angularity to cut down on noise and vibrations for a quieter, smoother drive and longer input seal life; dual-reduction architecture that significantly reduces stress and gear face pressure through the axle carriers; and an inter-axle power divider, which biases torque to the axle with the greater amount of traction.

Taken together, Horton said that these features allow Mack axles to achieve 1.5% fuel efficiency improvement.

According to Brian Daniels, manager of Detroit powertrain and component product marketing, the main benefits of an integrated powertrain come from the fact that all the components are designed together.

“When all powertrain and safety and technology components like the Detroit DD family of engines, Detroit DT12 transmissions, Detroit front and rear axles and Detroit Assurance suite of safety systems are designed and manufactured by the same source, there is the ability to create a level of integration that provides a much smoother, more efficient and safer customer/driver experience,” he said.

Dana’s Slesinski said that when selecting your truck’s drive axle, the main concern is choosing the appropriate drive axle ratio to provide the right level of startability, gradeability and optimum cruise speed.

“Each axle is designed to handle the various input torques from the engine, through the transmission, conveyed through the driveshaft to the axle, which in the end drives the tires to pull the loaded trailer,” he added. “The axle must also provide the strength to support the vehicle’s gross axle and combination weight ratings.”

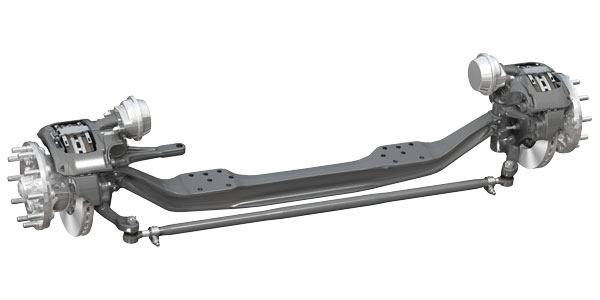

Slesinski went on to go over application considerations for the steer axle position.

“The steer axle bears a portion of the vehicle’s load, adding stability while accurately steering the vehicle in the right direction,” he said as he noted that key considerations when spec’ing the steer axle include track width, turn angle, maneuverability, weight, warranty coverage, disc brake compatibility, serviceability and maintenance intervals.

“Many applications often require enhanced maneuverability for factors such as getting into and out of loading docks with a Class 8 tractor, navigating residential neighborhoods for refuse vehicles and school buses, or even navigating twisting narrow roads for logging and mining applications,” he added.

This tendency is only increasing thanks to the last-mile delivery boom, which is leading to more trucks navigating city streets. Slesinski highlights the turn angles offered by Dana Spicer steer axles—up to 55 degrees.

…The suspension

Many of today’s suspensions are designed with the relationship to the axle in mind.

“The axle must provide secure attachment of the wheel-end and brake components while managing the stress and deflection caused by the load it is carrying plus the additional force inputs from the road,” noted Melanie Elliott, marketing manager for Hendrickson. “Suspensions must endure all the same force inputs as the axle, with the additional task of controlling the ride and handling of the vehicle. Under the trailer, the axle and suspension must work as a system.”

Bill Hicks, product manager—suspension systems with SAF-Holland, said that fleets should consider axle/suspension/brake systems rather than spec’ing individual components. These systems, he said, have been engineered to work together and in harmony with each component to optimize performance and durability.

“The mechanical spring suspension is continuing to grow its dry van market share, as it can provide fleets with a cost-effective and simple solution when compared to an air ride suspension,” Hicks noted. “New developments with composite springs, air disc brakes, and long-life wheel-end components are taking away the stigma of ‘old’ technology when fleets consider whether a mechanical or air-ride system fits their suspension needs best for new van trailers.”

Hendrickson’s Elliott also spoke about the importance of seeing suspensions as a system, rather than as a solo component.

“When integrating the axle, suspension, brake components, and tire inflation systems, the designer must ensure all these components are spec’d for the intended application and will work in harmony,” she said. “For instance, when spec’ing an axle, the designer must consider not only the desired load rating and track length, but also the suspension type, suspension mounting centers, brake chamber orientation, and potentially the installation of supply lines for tire inflation. Finally, the welding of the suspension system to the axle is a critical process to help ensure durability of the suspension system.”

According to Elliott, these principles were a large part of the design of Hendrickson’s Intraax integrated axle suspension system.

“The integration of all these components is done in highly automated and repeatable manufacturing processes. This optimized system allows for reduced weight and increased strength,” she said of Intraax.

…Air disc brakes

Dana’s Steve Slesinski pointed out that axles must be able to work well with your truck’s brakes, including the increasingly popular air disc brakes.

“The Spicer lightweight D-Series integrated air disc brake (IADB) steer axle supports air disc brake installations on 10,000 lb. through 14,600 lb. GAWR applications. When coupled with Dana’s lightweight beams, these steer axles are up to 76 lbs. lighter while offering improved stopping distance and less maintenance with Bendix ADB22x brakes,” he noted.

…Wide base tires

With benefits that include fuel efficiency, load efficiency and weight savings, market acceptance of wide base tires has been steadily increasing over the past 20 years. And if you’re spec’ing wide base tires, or thinking about it, know that this will affect your trailer axles as well.

“With the growing market acceptance of wide-base tires over the last decade, fleets have noted an increased sensitivity of the wide-base tires and overall axle stiffness in relation to tire wear,” SAF-Holland’s Hicks said.

Hicks said that for this reason, SAF-Holland designed its CBX integrated axle system to work with thick 5.75-in. diameter axles. This, he said, minimizes axle deflection, which results in reduced inside tire tread wear.

“Even if the trailer is equipped with dual tires, the wear on the inner tires can be exacerbated if the axle is not rigid enough to minimize axle deflection when loaded,” Hicks added.

He went on to highlight SAF-Holland axles’ strength-to-weight ratio, which he said minimizes axle deflection.

“Stiffer axle yields improve tire wear and also reduce the stress level of any/all axle weldments due to less deflection at key weldments,” Hicks went on. “All trailer applications will benefit from this advantage; however, those applications that run with wide-base tires would certainly see more of the benefit. Optional heavy-duty axles are also available for vocational trailer applications which typically demand on/off highway service duty capabilities.”

For more on this topic, click here to read 6×4 or 6×2 − How to spec the right axle configuration.