Swinger gladhands were designed to help eliminate damage due to pull-away or tight/jackknife turns, and to reduce impact where straight or angled gladhands are exposed to damage. They also reduce wear on your air lines by following the movement of the tractor, reducing the bending and flexing at the tractor gladhand.

To keep swinger gladhands in good working order, preventative maintenance should be performed every three to six months, or at each scheduled preventative maintenance interval.

General care of gladhands:

- Gladhand seals – Gladhand seals should be checked for wear and cracks that may cause leaks. Replace where any type of damage is present. If gladhand seals have dust flaps, replace when any flaps are torn or missing. If using filter screens, replace when damaged, torn or filled with

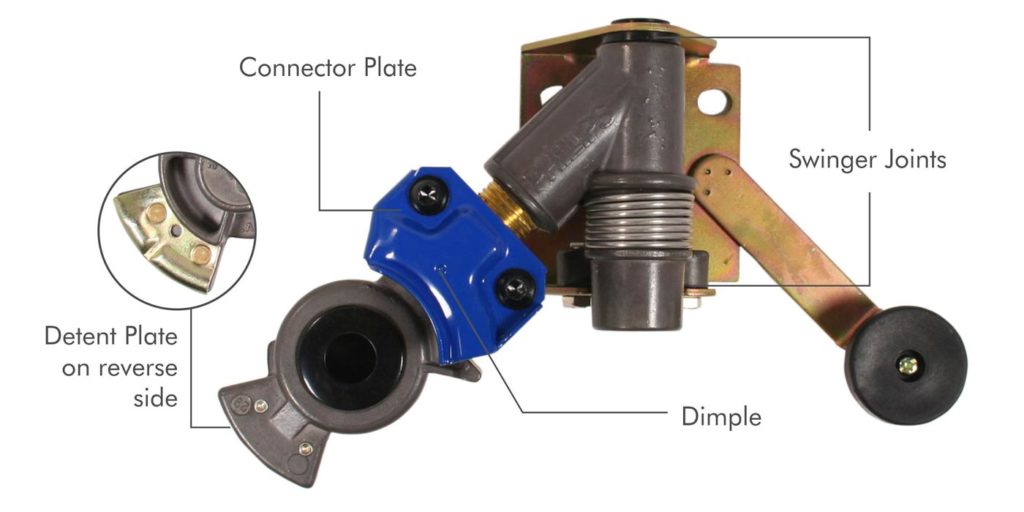

debris. (See fig. 1) - Signs of corrosion – Gladhands that show substantial signs of corrosion on the body, connector and/or detent plate should be replaced. It is suggested to use powder coated or anodized gladhands in highly corrosive environments. (See fig. 2 & 3)

- Connector plate – Make sure the small dimple on the connector plate is not worn down. If the dimple is worn down, replace the gladhand. If not replaced, coupled gladhands will leak air because they will begin to lose the ability to seal properly. (See fig. 4)

- Detent plate and rivets – Look for heavy wear to the detent plate as well as loose or corroded rivets. If the detent plate becomes loose it can eventually break off, making coupling impossible. Replace the gladhand where signs of heavy wear or corrosion are present. (See fig. 5)

- Routine replacement – As a recommended practice, gladhands should be replaced when air lines are replaced. Gladhand seals should be changed out once a year. These recommended replacement practices are suggested when signs of heavy wear, corrosion, cracking, damage, etc. are NOT visible, in which case they should be replaced much sooner.

Care of swinger arm and mounting plate/hardware:

- Swinger arm/spring – Joints should be blown clean during preventative maintenance inspections. A shot of penetrating spray can be used to keep the swinger operating properly.

- Mounting plate/bracket and hardware – Check for loose bolts and tighten where necessary to the proper torque. Check for signs of corrosion on the mounting plate and hardware. Replace if significant signs of deterioration are present that may jeopardize secure attachment of the swinger gladhand to the trailer.

This Tech Tip was contributed by Phillips Industries.