While a key goal for any fleet maintenance operation is to avoid unscheduled repairs, another cost-saving objective is to eliminate repeat trips to the shop for the same issue. In those instances, and especially when higher cost powertrain components are involved, unnecessary downtime and the impact on shop and technician productivity add up quickly.

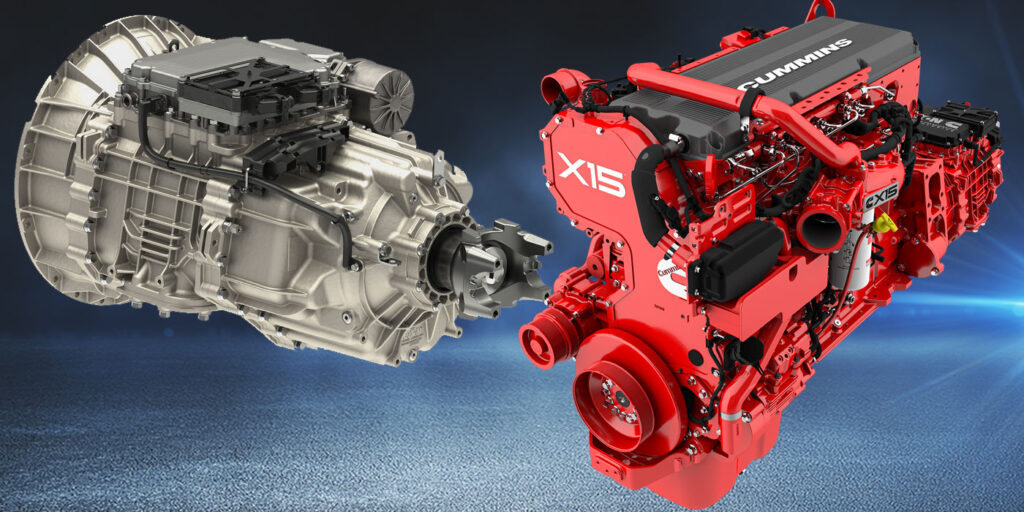

“Having the proper training increases the ability to fix it right the first time,” said Charlie McKinney, manager of technical communications and training at Eaton Cummins Automated Transmission Technologies. “It also very effectively reduces repair time. That’s why it is so important for technicians to be trained to diagnose and repair our products.”

Eaton offers a variety of computer-based training modules and in-person training sessions for manual transmissions, automated transmissions and clutches through its Roadranger Academy, McKinney noted. Additionally, several online training modules are available via syndication on some truck manufacturer customer Learning Management Systems.

Cummins, related Kristopher Ptasznik, powertrain TCO and consultancy leader, offers virtual and in-person training courses for technicians to become certified and authorized to work on the manufacturer’s engine and powertrain products. Online courses are available through the Cummins Virtual College or by contacting local Cummins distributors to register for online and in-person training on products and service tools.

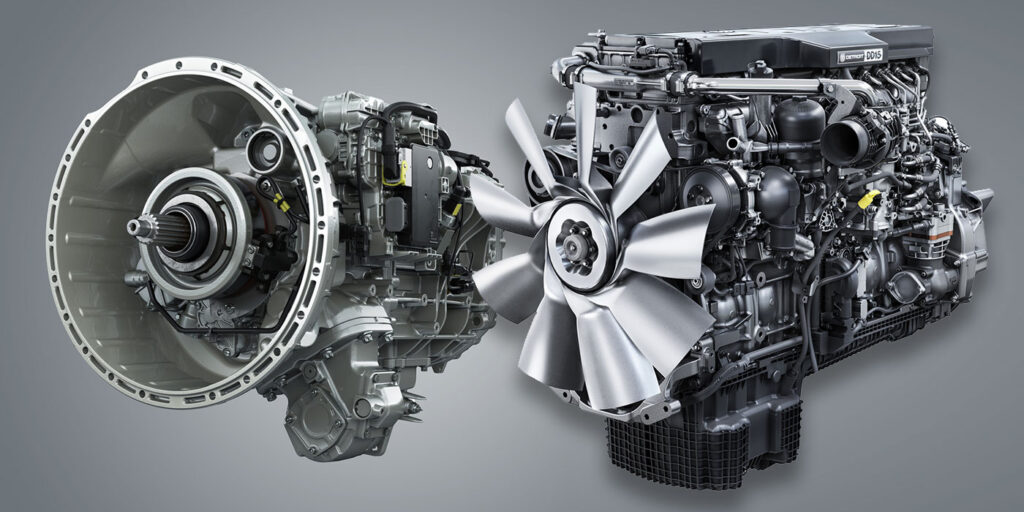

At Detroit, according to Len Copeland, product marketing manager, all technicians within the DTNA service network receive ongoing training education. “Some repair procedures require advanced levels of training to properly diagnose and complete,” he added. “We recommend connecting with a dealership or fleet representative before making an investment in training to complete these repairs.”

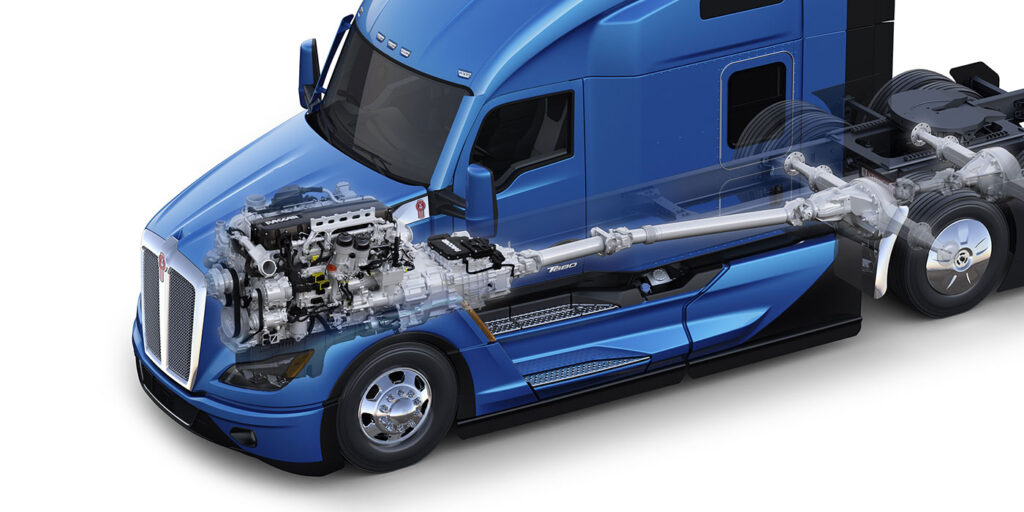

For PACCAR powertrains, Kenworth dealer technicians receive a combination of up to 250 hours of classroom training and more than 80 hours of online module training. “This rigorous training ensures the technicians have the knowledge and skills to service any powertrain component on every model,” said Mike Gaudio, Kenworth dealer service training director. “Recurring classes and quarterly workbook completions are required for technicians to maintain their proficiency on the latest technology.”

Manufacturers also provide a wide range of maintenance information on powertrain components. All Detroit Service Manuals, for example, are accessible online. “The guides are regularly reviewed and are the most up-to-date source for all Detroit maintenance,” Len Copeland said. “When changes are made, it is typically due to the accumulation of enough data to extend a service recommendation or the introduction of new products.”

Kristopher Ptasznik pointed out that the source of all maintenance requirements and tips for Cummins-powered engines can be found in the Owner and Operators, and Operation and Maintenance, manuals on QuickServe Online, where customers can register up to four free engine serial numbers to access the database of manuals related to their equipment. In the routine maintenance section of the Operation and Maintenance Manual, customers will see recommended maintenance intervals and procedures to complete the maintenance-related items, he added.

“The information provided in the Operation and Maintenance Manuals, on product web pages, and in end-user and dealer presentations is updated to include any revisions or changes to the maintenance schedule,” Ptasznik also related. “Maintenance information is updated on an as-needed basis. Typically, when a product is first launched the maintenance requirements and schedule will reflect any changes, and previous product maintenance schedules may be updated if the change is backward compatible.”

At Eaton, noted Charlie McKinney, transmission and clutch maintenance requirements, including lubrication intervals, are in manuals that can be found online. Additionally, each product has its own set of service literature, including a Troubleshooting Guide and Service Manual. “A product’s maintenance requirements are established during development,” he said. “A change in maintenance requirements would only take place if there are product design changes or if additional testing confirms that a change was warranted.

“Diagnostic information can be found in the product’s Troubleshooting Guide,” McKinney continued. “That is updated frequently and is affected by emerging technology, service tool software updates and diagnostic optimization based on real world service data. For a new product, monthly Troubleshooting Guide updates are commonplace.”

On-board diagnostics can facilitate powertrain component service by providing a starting point, said Eaton Cummins’ Ptasznik. “With diagnostics tied to specific fault codes, and various fault code tools available for technicians, that data can help the troubleshooting process,” he continued. “Once the faults are understood, service-oriented software can provide recommended troubleshooting trees to help discover the root cause. Additionally, due to advancements, select fault codes do not require troubleshooting and instead allow for direct component replacement, which helps eliminate diagnostic downtime.”

“Telematics data helps technicians diagnose, troubleshoot, repair and document, as well as ensure they have the right tools needed to complete a repair, contributing to less time in the shop,” said Detroit’s Copeland said. “Service managers use telematics data to gain insights and understanding into service intervals on their vehicles, and determine what needs to be serviced soon versus what needs to be serviced now, allowing for maximum uptime.”