What was once an abandoned Dodge dealership in Albuquerque, NM, has transformed into a hub for pioneering trucking innovation and technological advancements. At a glance, it might look like a typical fleet lot, but look closer and you’ll see a host of advanced sensors mounted on trucks and while there’s a driver in the seat as it rolls onto the road today, that won’t always be the case.

It’s the home of Torc Robotics, a company founded 17 years ago, that aims to increase trucking safety by developing automated self-driving technology. Torc Robotics has reached a mile marker on its journey toward fully autonomous Level 4 driving, and I had the chance to hop into the truck and see it for myself.

After arriving at the facility, I met with the group responsible for the daily operations and success of the testing center. Klara Oberhollenzer, engineering and product director for mission control and logistics integration, walked me through the technology used to monitor all the data obtained from the trucks coming in and going out of their driveway. One of those self-driving Freightliner Cascadias was going to shepherd me around the Albuquerque interstate.

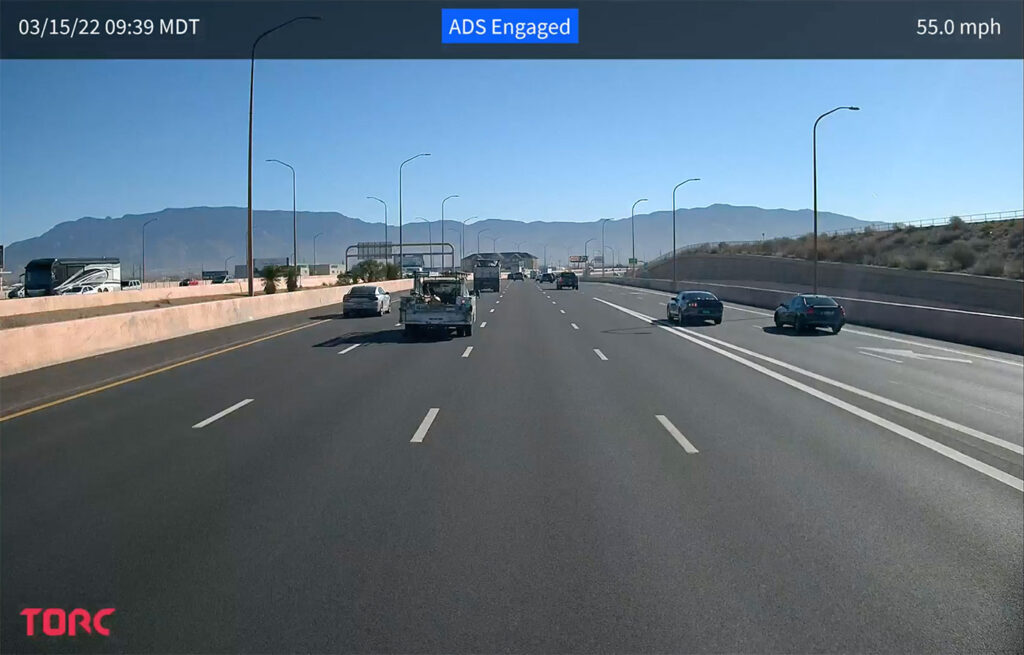

Even though a safety conductor and driver occupy the front seats throughout the development, the autonomous truck was still operating at a Level 4 autonomy when on the highway. The safety driver operates the truck to the highway and back to Torc Robotics HQ. As it stands now, autonomous surface road navigation is considered “high risk” and there is too much activity outside the scope of the sensors, Andrew Culhane, Torc chief strategy officer, explained. However, when it reaches commercial use, there will be no one inside of the truck and all operations will be overseen by mission control, a remote location where fleets can monitor and manage their autonomous trucks.

While this is a triumph just over the horizon, no specific deadline can be determined. According to Michael Fleming, CEO and founder of Torc, safety is the number one priority and until absolute performance is a guaranteed outcome, they continue working to develop the technology.

Oberhollenzer detailed the ability to track a live video feed, vehicle location, speed, ETA, safety conductor feedback, and condition of the autonomous system, which was just a sampling of Torc mission control capabilities. This system gathers a substantial amount of data from every trip. Not only is the data saved and analyzed by logistics specialists, but also by the engineers working to improve the system’s behaviors with each test drive.

By combining the courtesy of human driving behavior, such as creating lane space for people to merge, with the precision of the autonomous driving technology, the system achieves a calculated and conservative operation style.

Speaking of combining data, through the integration with Daimler Truck North America (DTNA), Torc has been able to analyze both the data from their facility’s trucks and the statistics DTNA has collected from previous manually-driven fleets.

The continuous collection of new and existing data, along with the frequent feedback received from test drivers and safety conductors is ingested and retained by mission control. The attainment of both qualitative and quantitative information helps to make the system more robust and increasingly functional.

After getting a chance to view my test route and driver feedback from a trip earlier that day which discussed traffic patterns and conditions, it was time to head to the lot.

There to greet me outside was Culhane, Garen Head, safety conductor, Paul Norero, test driver, and, of course, the 80,000-pound self-driving behemoth ready to take me for a technology-enhanced ride. The stand-out difference from your typical Freightliner Cascadia was the plethora of components used to transform this heavy-duty truck into a second-generation autonomous vehicle. Cameras and sensors canvassed on the dash, above the roof fairing, clung to the side-mirrors and crouched the doors.

“The lidar, the radar and the cameras work together to get a full picture of the world,” Culhane said. “We are narrowing in on the optimal sensors for this application and anticipate that the gen three model will incorporate a redundant chassis.”

The ride started out just like any other–controlled completely by the driver–until we approached the onramp to the Coronado Freeway (40 East). A blue light illuminated the ceiling and, just like that, the system was engaged and the truck merged onto the freeway under its own autonomy.

As the truck drove itself, test driver Norero and safety director Head discussed the vehicle’s ride and performance. The driver, while not steering, maintained hand-to-wheel contact for the entirety of the trip as a way of analyzing the behavior of the torque and how the ride was impacted by the system’s operations.

The computer screens positioned behind the passenger seat displayed the real-time scope of our surroundings including not just the road, but the behaviors of the vehicles within range.

“Our trucks are looking at all of the lanes around us at all times. The system is tracking the availability of every adjacent lane constantly,” Culhane said.

There is no guessing, according to Culhane. The system’s use of traffic data, weather data and road data ensures that the computer’s driving patterns are conservative and precise in its nature. Because of the system’s ability to predict driving behaviors, typical situations become increasingly avoidable.

“We have the ability to very accurately know the position and speed of everything around us,” Culhane said. “We also know what our standard braking distances are for a loaded trailer. Because of this, we can stay out of a lot of challenging situations other drivers get into.”

Once you get used to the fact that the truck is driving itself, you start to see the deeper implications. Take distracted driving for one: The U.S. Department of Transportation’s National Highway Traffic Safety Administration stated that distracted driving took 3,142 lives in 2020. Speeding killed 9,478 people. Torc Robotic’s self-driving truck isn’t going to take its eyes off the road to check its text messages or speed up to chase down a vehicle that just cut it off.

“Our autonomy doesn’t get frustrated or experience road rage. It isn’t watching the hours of service or trying to make it to the next rest stop,” Culhane explained.

As more vehicles poured onto the congested highway, my nervousness came rushing back. But the truck was unphased at the congestion, keeping pace with the flow of traffic and confident in its decisions.

Within 55 minutes we arrived back at the Torc facility. The truck successfully drove on both 25 North and 40 East, climbing up Seville Hill and coasting back down. The only time the system was disengaged and controlled by the driver was at the very beginning and end on city streets.

The various factors that play a role in driving complexity, such as traffic, directions and geographic layout, were easily maneuvered by the system making for the most exciting, yet uneventful truck ride ever.

“For better or for worse, riding in an autonomous truck tends to be very boring,” Culhane said.

“Which is good!”