I grab the bread and begin to unwind the bag twist tie only to discover it grows tighter. Maybe the wire in the tie got knotted together? Or maybe someone thought twisting the tie 50 times would be funny. Am I tightening the tie instead of loosening it? Turning the tie counter-clockwise to the left should be releasing the miserable piece of wire.

But wait!

The tie is getting more twisted, not less. Of course, I shouldn’t complain too much about the tie, at least it wasn’t on the floor for the cat to play with. Plus, I have no doubt twisted the twisty in the “wrong” direction myself on more than a few occasions.

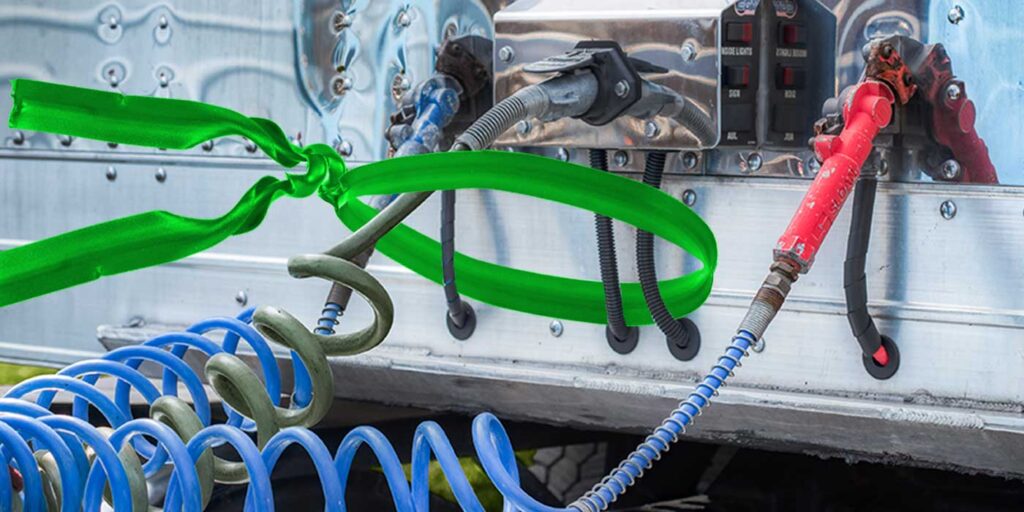

Lock challenges do not begin and end with bread bags. When servicing trucks, electrical connectors present challenges that will be frustrating when the technician doesn’t know how the connectors lock together. Without the special tools to unlock the connectors or the process to disconnect them, some connectors will be similar to a magic puzzle box.

Unlocking the electrical connector puzzle

It is not uncommon to be working on vehicles where the electrical connectors appear to have been previously disconnected with a claw hammer. The connectors will be misshaped and no longer able to lock in place, making it necessary to replace the connectors. Damaged connectors allow for loose connections and water intrusion, which can lead to additional issues.

Keeping circuit connections trouble free

In most instances, the service information will include details about special tools and procedures for disconnecting connectors, along with the same for removing and installing terminals for the connector. In addition, it is important to know that many connector terminals require the use of specially sized terminal probes to avoid expanding the female terminal and creating a potential open circuit point.

Terminals damaged during the diagnostic inspection may lead to new problems or bring about an assumption that a replaced component is faulty. Taking the time to understand how systems and components should be tested will prove helpful in making timely and accurate diagnosis and repairs.

Electrical connector locks do not need to be frustrating. The connector locks and seals play a vital role in ensuring electrical circuit connections remain operational and trouble free. Improper procedures when working with electrical connectors may not be noticed immediately. It is quite possible that technicians will encounter connector issues that started during other service issues long before any issue with the circuit resulted.

The care a technician gives a system today may potentially affect the operation of the system or vehicle for years to come. So be patient, be diligent, and provide the best service possible to keep customers coming through the door.

Additional tips for repair and maintenance of Class 4-8 trucks may be found in the Mitchell 1 ShopConnection Truck blog.