Engine oil is more complicated than a viscosity number. We have a lot to get through, so let’s get to it. Read on to learn about FA-4 oils; the latest in engine oil technologies and advancements; the importance of used oil analysis; and the importance of using the right oils and greases throughout the rest of the powertrain.

Topic 1: FA-4 oil

API CK-4 and FA-4 oils were released in 2016, and you likely heard a lot about them at the time, when they were known as PC-11. So, four years later, how widely used are these new oils?

The answer is a bit of a mixed bag. While CK-4 is a direct upgrade of the previous CJ-4 category and has replaced it throughout the industry, FA-4 adoption has been slow.

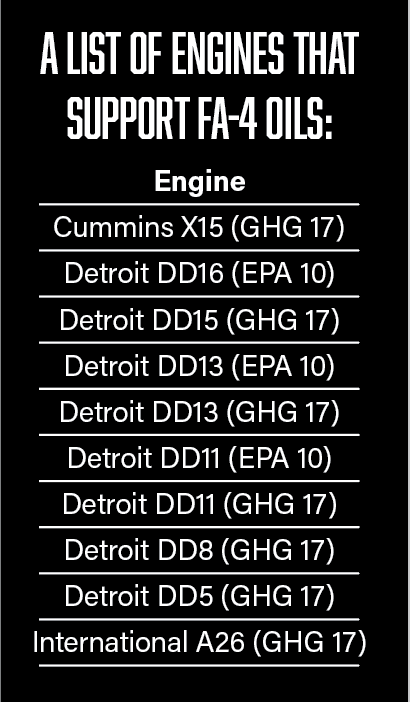

Only certain engines from Detroit, International and Cummins support FA-4 oil as of now. PACCAR, Volvo and Mack have yet to incorporate this category of oils, so keep that in mind when making your oil spec’ing decisions.

“Given the performance benefit offered by API FA-4, I think collective lubricant and OEM industries would like to have seen greater growth,” says James Booth, commercial sector manager for North America at Chevron. “That said, we are seeing notable uptake from those fleets that were early adopters of 10W-30. They typically are fleets accumulating high mileage per unit (and therefore have high fuel costs), and their fleet truck age is two to four years.

“The main barrier to adoption has been the mix of fleet. If you look at the U.S. market as a whole, the number of HD trucks with engines approved for API FA-4 is relatively high. However, what we have seen in practical terms is that if a fleet of 100 has just one engine not approved for FA-4, they will not adopt FA-4.”

“We anticipated that it would take time for trucks that require FA-4 oils to make their way into fleets,” says Dan Arcy, global OEM technical services manager for Shell Lubricants. “It has been a slow process and some fleets will not use FA-4 oils until most of their fleet requires the oil. With trucks being in a fleet for about five years, many of the older trucks are still being phased out and we expect the use of FA-4 oils to increase.”

Chevron’s Booth adds that to see an increase in the rate of FA-4 adoption, we would either need to see another OEM approve the oil, one or more OEMs increase backward compatibility, or, failing that, simply wait a few years for a larger proportion of the market to be FA-4 approved.

Adoption rates aside, the oil companies report that fleets who are able to adopt FA-4 will see numerous benefits.

“Newer engines run at higher temperatures which can stress conventional lubricants and accelerate the oxidation and degradation of the oil,” says Darryl Purificati, OEM technical liaison for Petro-Canada Lubricants. “However, FA-4 oils can cope with the increased environment; by flowing more quickly through the engine, they provide vital lubrication to internal hardware. The ease of flow also reduces friction and fuel consumption, and lowers exhaust emissions to improve the overall efficiency of the vehicle.”

Topic 2: New engine oil technologies

CK-4 and FA-4 represent the present of engine oils, but now, let’s talk about the future.

“The ongoing quest for better performing, longer-lasting lubricants has led to dramatically improved finished lubricants,” Purificati says, mentioning CK-4 and FA-4 oils as an example of this. “While for fleets this has meant increased fuel economy and longer drain cycles, for the lubricant industry, it simply means staying ahead of engine requirements to ensure maximum operational efficiency.

“What it most certainly means is that as new engines emerge demanding more performance for less emission, there will be the equivalent oils—which is good news for both motorists and fleet operators.”

“With the constant push for engine efficiencies and lower emissions, we expect to see engine oils continue to adapt to meet the needs of engine manufacturers,” Shell’s Arcy says. “This will likely include the ability to manage even higher temperatures, and viscosities will almost certainly continue to go lower to drive improvement in fuel economy and efficiency.”

“The combination of government regulation and OEMs competing on total cost of ownership continues to drive powertrain design and maintenance practices, which demand improved fuel efficiency and drain interval from the lubricant industry,” Chevron’s Booth says. “Fuel economy improvement is primarily driven by lower viscosity. We will likely see very low viscosities like 5W-20 in the years ahead.”

The key, Booth adds, is to deliver these viscosities without sacrificing wear control—and at these low viscosities, it requires novel additives and formulating.

Jim Salmon, technical manager/sales at D-A Lubricant Co., also notes the growing trend toward lower viscosity in order to improve fuel economy.

“The No. 1 cost for over-the-road fleets is fuel,” he notes. “If you can improve fuel economy by just 1 or 2 MPG, depending on fleet size, annual savings can be in hundreds of thousands, if not millions, for a fleet with 200 or more trucks.”

Topic 3: Used oil analysis

We did an in-depth story on used oil analysis back in May, so we won’t get too much into the details here. Suffice it to say: engine OEMs and oil providers alike strongly advocate used oil analysis.

“A comprehensive oil analysis program is the only way to get a good look at what is going on inside a component,” says D-A Lubricant’s Salmon. “As far as when to sample, we recommend at least with every oil change. For continuously operating equipment, it may be necessary to sample a few times between drains. For the customer, it can help find a small issue before it becomes a big issue.”

Keep in mind: the most important thing you can do before starting a used oil analysis program is to speak with your oil provider so that you know what you are looking for from this process, and what steps you can take after the analysis is completed.

Topic 4: Oils and greases for the powertrain

The engine is not the only component for which oils and other lubricants are important. Fluids and greases for your transmissions and axles are an important aspect of any fleet’s maintenance program.

Chevron’s Booth notes that transmission and axle lubricants can lead to improved fuel efficiency. He adds: “Coolants and axle fluids are often referred to ‘fill for life,’ though that doesn’t mean they don’t need some attention as part of a maintenance plan.”

When it comes to greases, there are a few things you’ll need to keep in mind.

“Firstly, it’s vital to have the correct grease in the right grease point, in the correct amount at the right time,” begins Petro-Canada Lubricants’ Purificati. “When choosing a grease, the application requirements will dictate the properties needed. A grease designed for a low-temperature operation might not provide good lubrication in a hot environment due to the thickener and base oil properties, as the grease would be too thin to stay in place in a hot environment.

“The bearing or lubricated part dictates the quantity of grease to use. However, the re-greasing frequency is determined by the operating parameters and the environment. A vehicle in Hawaii where the climate includes heavy rains and exposure to saltwater, humidity and heat may require a grease to be applied more often to protect from these elements. This would typically be much different than a grease for an inner-city vehicle in Pittsburgh.

“And second, each truck has its own unique requirements which means that a ‘one-grease-fits-all’ philosophy is often not possible. To provide proper and lasting protection, more than one grease is often needed to meet the different lubrication requirements of the various components of a truck’s hardware.”

Purificati concludes that before consolidating your greases, it’s important to seek expert advice from a lubricant technical advisor. They will be able to share their insight into how you can safely reduce the number of greases in your workshop without compromising the protection of your hardware, to help keep your fleet on the road and prevent unplanned downtime.

Shell’s Arcy echoes the importance of using greases that meet your equipment specs—for instance, choosing a grease that can handle harsh conditions like high temperatures, water wash-out, dirt and contamination, if need be.

“Transmissions have long drain intervals which can go up to 500,000 miles,” he adds. “Oil analysis each year from the transmission and axle will help ensure that they are operating properly and help discover any issues before they become major problems.”

RELATED: Read more about making the right grease choices here.