And yet the desire not to have to pay our own bills is equally strong. We’ve all had that moment when a bill arrives and your immediate, instinctive thought is “I’ll pay that later.” Prompt, on-time and accurate payments might make the business world go around, but this business utopia is harder to achieve than you might think.

It’s hard to keep track of what bills aren’t being paid, or when they’re being paid, or if they were paid in the wrong amount, or you didn’t bill repairs or time correctly. This is why many of today’s shops are reliant on invoicing software, both for work orders and for parts sales. Invoicing software typically runs on your computer and communicates with other devices throughout the shop such as the tablets that technicians may be using. It often integrates with other software you may be using. Let’s take a look at four major benefits of invoicing software for heavy-duty shops.

Benefit #1: Increasing tech efficiency

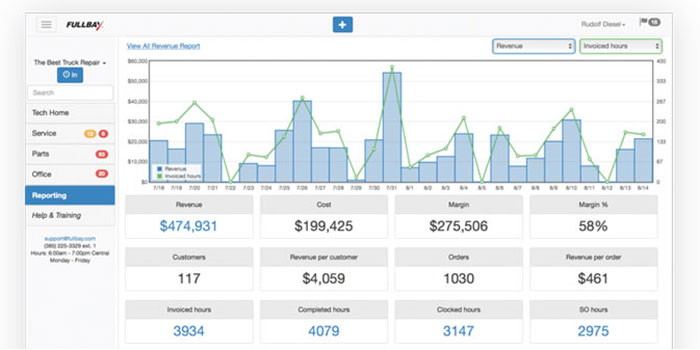

“The number one thing a shop can do to increase profitability is to increase tech efficiency,” says Jacob Findlay, founder and chief executive officer of Fullbay, a provider of invoicing and parts inventory management software. “There’s nothing that comes even close to that. Our software is built around driving efficiency in the shop, making sure that when the techs are there, they’re able to turn wrenches instead of standing around waiting for parts, waiting for authorization, etc.”

Invoicing software also allows technicians to make notes about when they last repaired the truck—something that Kenny Nau, director of sales for Pluss Corp., developer of Vision invoicing software, notes saves time and can potentially help with customer retention. Nau says that using invoicing software allows you to go over the invoice step by step with the customer; “telling the story,” as he puts it, of the work that was done on the truck.

“If the customer says, ‘When did you work on my truck last?’ Boom—I can have that past work order information up on the screen within seconds,” he adds.

In Trimble’s TMT Service Center shop management system, according to Renaldo Adler, industry principal for asset maintenance with Trimble Transportation Enterprise, technicians make use of kiosks, which he describes as being similar to those at airports used to check into flights.

“The technician logs in so you know what time each technician came to work, and then he has a list of repair orders or units assigned to him,” he said. “He’ll click which one he wants to start working on, and it starts the clock.

“He goes back to that kiosk and says, ‘Here are the parts I need.’ When he’s finished he puts in his three C’s—complaint, cause and correction—and any notes about what he may have done. And if he’s working on a particular vehicle, he may find some other problems—for instance, if he needed to replace the wheel bearings when he did the brakes—that can be added to that repair.”

Benefit #2: Billing your time correctly

One of the biggest benefits of technology is the ability to gets things exactly right. Not your best guess, not close enough—exactly right. Using software for things like invoicing removes human error from the equation, making sure you know exactly how much you should be charging—and that it’s being charged.

It may seem like a small thing, but this is where a lot of shops lose money—on those margins, in that difference between “close to” the right number and the exact right number.

“There isn’t a shop on the planet that bills 100% of their time,” Pluss’s Nau says.

He then gives an example: “Let’s say I have four technicians. I pay them each 40 hours a week, which means I’m paying for 200 hours a week, and 800 hours a month, of time to sell. Because that’s really what techs are doing when they provide labor: they’re selling their time.”

Nau says that in his experience, many shops are billing about 80% of their time—so in this example, the shop is billing 640 hours of time, rather than 800.

“So,” he says, “I lose 160 hours that I can’t bill. And if my shop rate’s $90 an hour, for example, then I’m leaving $14,400 on the table that month. I lost $14,400 in labor.”

So how do you recoup that? Nau recommends his software’s time clock feature, which allows for more accurate measurements of how long a particular job takes:

“Let’s say for a particular brake job we always charge seven hours, but on average it’s taking nine. I need to start charging more for that because I can’t afford to keep losing two hours for every one of those brake jobs I do.”

Mitchell 1’s Manager SE Truck Edition shop management system is specifically designed for independent shops, who may not have the same advantages as fleet shops and tend not to use as much technology.

“Having a system in place to keep track of customer invoices is not something that has been a standard practice in independent shops,” says Kristy LaPage, business manager for Mitchell 1’s commercial vehicle group. “That’s just the nature of the business. If the shop is primarily dealing with over-the-road, for example, it may be an inconsistent customer base, and the process is get it in, get it out. It helps to have that visibility within a shop management system to manage that, make sure you’re charging correctly and getting paid correctly.”

LaPage describes Manager SE Truck Edition as a place to easily store and access customer records—everything from invoices to creating a quote.

“Even to this day, you’ll still see quotes written on scraps of paper or written on post-it notes and given to the customers or, more frequently, just a verbal quote over the phone,” she notes.

Benefit #3: Integration

The modern shop is a world of multiple screens, devices and software systems, so the more these systems can work together, the better and easier it makes things for everyone working there.

For instance, Fullbay’s Findlay estimates that around 90% of heavy-duty shops are using QuickBooks as their accounting service, adding that the benefit of integrating with QuickBooks through an invoicing software is that it eliminates redundancy and double-entry.

“Customers say that the ability to export to QuickBooks saves them so much double entry in time versus having to do the work order and then basically redo that work order on an invoice and an accounting system. This eliminates that step,” says Kurt Claussner, president of Fleetsoft, a provider of invoicing and parts inventory management software.

“All of the work that the technicians do at the point of sale—work orders and putting parts and labor on—that information automatically gets sent to the accounting system so that there’s no redundancy,” Nau says. “If you’re using QuickBooks, that information all flows over to QuickBooks, and updates it.”

LaPage highlights the integrations offered by Mitchell 1’s system. “It integrates with the system’s repair information, so when you’re creating an invoice for the customer, you can link that to the labor times and procedures that are already in the program,” she says.

Additionally, Mitchell 1’s software integrates with Accounting Link, which helps it “talk” to multiple accounting software options that the shop might want to use, including QuickBooks.

Benefit #4: Making better use of your time

All the aforementioned benefits have the cumulative effect of allowing both you and your technicians to better use your time.

Fullbay’s Findlay says it allows the service manager to act as the “quarterback” of the shop, without worrying about some of these little things.

“Fullbay handles the order to cash from the repair requests all the way through invoicing and receiving payment, and all the players in the shop are in Fullbay using the software to run the shop,” he says, continuing the metaphor. “So the service manager is basically quarterbacking the shop, since he or she is able to see which techs are running efficiently, who needs help and which jobs are ready to authorize payment.”

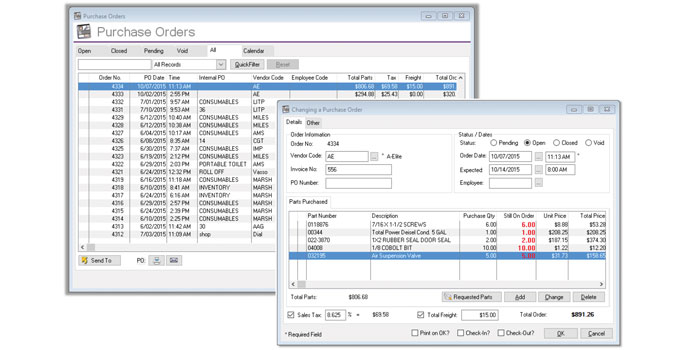

Fleetsoft’s Claussner highlights the software’s ability to save shop managers time doing double-entry.

“The main feedback we receive from customers is about the time savings,” he says. “The software keeps a history of all the invoices, and you can get reporting of how much you’ve invoiced and what your profit is. If you have a regular shop management system that doesn’t do invoicing, you have to make the work order and then create a whole new invoice in your accounting system to do the billing.

“Here,” he continues, noting the completed work order in Fleetsoft, “you do the work order, you click a button, and there’s the invoice. You don’t have to reenter the data.”

“The service manager sees what’s going on and he can immediately generate an invoice,” Trimble’s Adler says. “He doesn’t have to go get that work order and key it into some system to generate the invoice; it’s being generated as the work’s being done.”

Adler says that Trimble’s system is specifically geared toward fleets that run their own shops. It allows them to integrate and have invoices sent directly to the fleet manager electronically.

“It’s a benefit to the fleet because they don’t have to deal with paper invoices either,” Adler says. “That’s a big benefit I think service providers need to look at: being able to get the data back easily to the fleets so they can get a true total cost of ownership on their vehicle.”

Pluss’s Nau points out that the software can also help resolve or avoid disputes with customers. He gives the example of the shop recommending a repair, the customer declining, then coming back later and complaining that there’s an issue that wasn’t dealt with before. Now, Nau notes, there’s a paper trail showing that the repair was recommended and declined by the customer.