It’s probably not a surprise that parts costs can account for a substantial portion of a fleet’s maintenance and repair expenses. What’s not often as apparent, however, is the cost of managing parts, and the ways that activity can be streamlined to generate savings and improve a service operation’s productivity and efficiency.

“Fleet operations often spend a large amount of time managing parts and other supplies, such as tires, batteries, fluids and lubricants,” said Will Wycks, senior vice president, product and marketing at Chevin Fleet Solutions. “Fleet inventory management software can be of great benefit, helping fleet maintenance operations improve visibility, become more organized and make more informed operational decisions.”

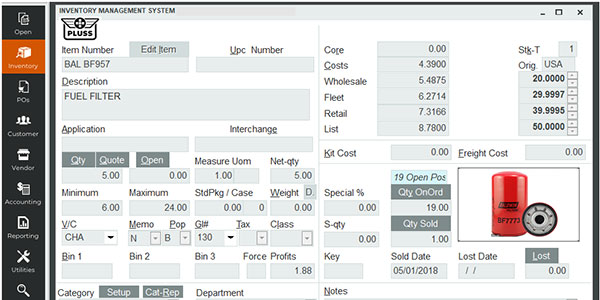

In addition to time savings, noted Cianna Kennedy, Pluss Software’s director of sales, software saves you money. “It’s difficult to manage what you’re not able to measure,” she said. “The value behind software ultimately lies in the visibility and tracking it provides.”

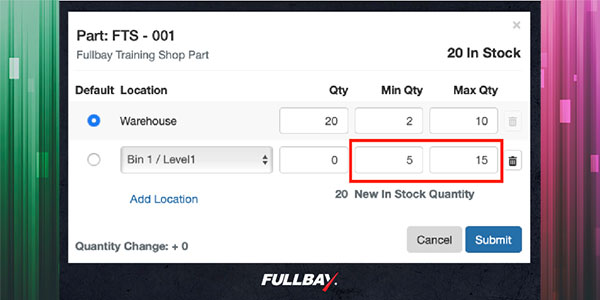

Louis Barrales, product marketing manager at Fullbay, listed a number of benefits fleet maintenance operations can realize by using parts inventory management software. “Adding, editing, and uploading inventory is easy with management software,” he related. “Parts are constantly coming in and out of the shop from orders and from using inventory. With software, your inventory can be managed automatically.

“Parts are naturally going to be in different places, in bins for different trucks, in the shop and at bays,” Barrales added. “With inventory software, whoever needs to pull the part always knows exactly where to find it.”

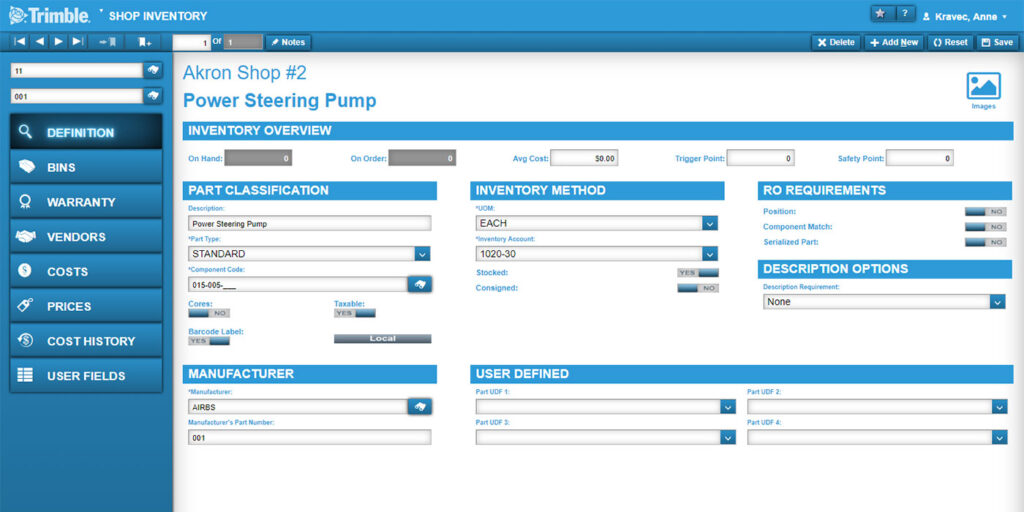

With proper implementation and setup, the capabilities of parts software will become immediately available to assist in inventory management, noted Dave Walters, sales support engineer for Trimble Transportation. That includes the ability to receive parts from a purchase order and reserve them for a particular repair order.

“Those features also include inventory usage tracking, cross-referencing of parts and the availability of pre-printed bar code labels,” Walters said. “The systems can automatically generate return tags for items covered by warranty and give technicians the ability to requisition parts directly from bays on workstations and charge out parts in remote locations.”

Parts purchasing practices are refined with advanced software. For example, Trimble’s Dave Walters pointed to automated parts ordering and backorder capabilities based on calculated turn rates and recommended inventory quantities. There is also the ability to enforce bid pricing on high-volume parts.

“Without inventory management software you cannot manually track the supply of every part to ensure you have what you need,” Fullbay’s Louis Barrales said. “By setting minimums, your software will automatically order parts as you go below that threshold so your inventory is always full. In addition, with cycle counting in the software, you will have a live feed of actual inventory. That lets you make real-time inventory adjustments.”

Cianna Kennedy at Pluss Software noted that there can be a lot of time wasted searching for parts if software isn’t helping you. “With the right inventory management tools, you can see exactly where a part is located and whether or not it is in stock before a technician ever leaves a workstation,” she said. “If a part isn’t in stock, inventory software can handle interchanges to help you quickly find alternative parts that are on hand to satisfy the job.”

By integrating parts management software with suppliers’ systems, according to Chevin’s Will Wycks, fleets can ensure data accuracy and reduce demands on administrative, financial and other departments, helping to reduce inventory costs and staffing requirements. For example, automated inventory replenishment based on parts use and upcoming needs, and seamlessly issuing purchase orders to preferred vendors, saves time and effort.

Fleet maintenance operations have unique parts management needs, Pluss Software’s Cianna Kennedy said. “It’s important to look for solutions that are designed to accommodate them,” she added. “Those operations can save a substantial amount of time and money through better visibility and tracking, but that requires the right tools.”

For Will Wycks at Chevin, it’s also about long-term value. “Inventory management software can be used to help identify repetitive failures or low-performing parts,” he said. “It can be used to perform comparative analyses between manufacturers and parts and build a more in-depth picture of component longevity and costs for each vehicle in a fleet.

“As a source of data on failures and usage trends, parts management software helps make more informed and effective vehicle and replacement parts purchasing decisions,” Wycks added, “reducing downtime and returning vehicles to service faster.”