Controlling maintenance costs, hitting that perfect level where costs are under control as much as possible, uptime is maximized and unplanned events are limited: these are the things that keep fleet managers up at night, and the things that drive many of their spec’ing choices.

But it’s also worth thinking about your trucks’ maintenance intervals. What if a fixed interval based on mileage isn’t optimal? What if there’s a better way?

“Currently, most fleets maintain their trucks on mileage-based fixed intervals, depending on what the truck OEM or engine manufacturer says about their duty cycle, etc.,” says FleetguardFIT Business Director Darren Liu. “We know that when we design the filters and the engine oil, how long they will last is typically based on a broader range of applications. When they follow the fixed intervals, oftentimes there is still life remaining in the filters or in the oil that they throw away.”

Enter condition-based maintenance programs. Liu says that the idea behind condition-based maintenance is to better utilize the life of things like oil and filters to reduce costs.

“The fixed interval is often based on a typical application with some safety margin, but we know every fleet and every truck will operate differently,” he explains. “In reality they could be changing it too soon because there’s remaining life in the filter or oil that they’re not fully utilizing. Or alternatively, a truck that typically runs a light-duty cycle is getting into heavier duty because of the environmental conditions or some other factors and needs to be serviced earlier than usual. So the benefits of monitoring in real-time constantly is that the customer will have the insights to say, ‘hey, the fuel filters are really plugging faster than they typically do. Maybe that’s a batch of bad fuel.’ Then you pull the vehicle in sooner than the typical service cycle.

“It’s rare that you can really hit that perfect maintenance timing for every truck based on that fixed interval. By having the insights about what’s the condition of my filters and oil—how much life is predicted; how many miles—the fleet can schedule the maintenance event based on every truck’s condition, not having to follow a fixed interval.

“In terms of savings for the fleet it is twofold: Reduce the hard dollar spending on these consumables, but also reduce the likelihood to have a breakdown event and major repair,” he concludes.

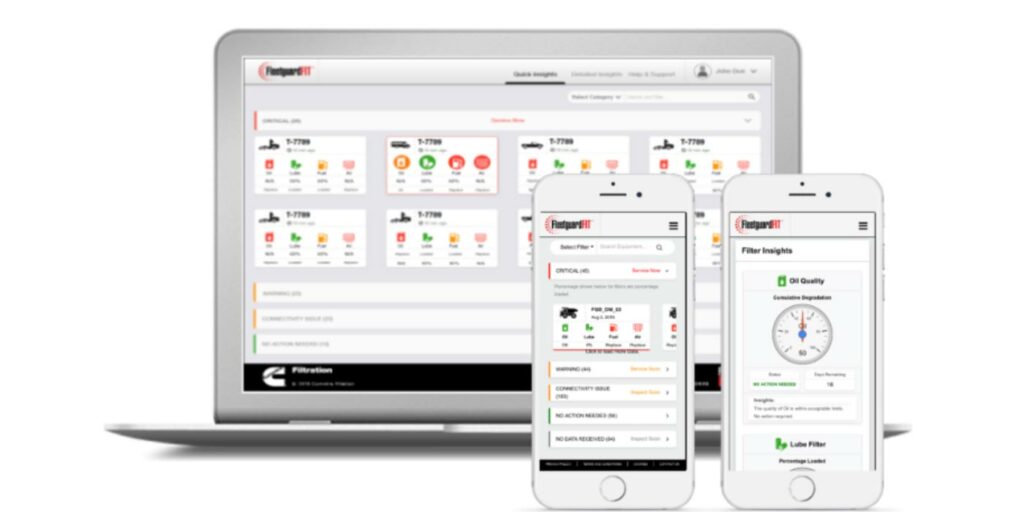

The idea of condition-based maintenance was one of three driving forces behind the development of FleetguardFIT, a sensor and cloud based monitoring system for filters, lube oil and hydraulic fluid that provides real-time status updates and remaining life predictions so maintenance can be based on real-world conditions, instead of guesswork.

FleetguardFIT can be used with any engines across the globe, and works best when genuine Fleetguard filters are in use on the truck.

In addition to taking advantage of condition-based maintenance programs, Liu says that the second reason is that “we didn’t really have direct insights from the condition of operation for the filters and the condition of the engine oil quality, which are key elements around the engine to help the moving parts work correctly and maintained well.

“It would be great if we knew: what’s the filter restriction; what’s the filter loading trend; what’s the engine oil degradation level and anything abnormal that happens in those systems, to better inform the fleet about any preventative maintenance needs or even potential issues to avoid progressive engine damage and reduce unplanned downtime,” he says.

“The third one is, we’re seeing more and more telematics connectivity and more sophisticated fleet management systems becoming a norm for the fleets. This made it possible to have the infrastructure to collect more data around the engine, filters and engine oil quality, etc,” he adds.

Here is a particular use-case for FleetguardFIT, shared by Shantanu Nadgir, Business Development Manager for FleetguardFIT:

“We have worked with customers out in the field, called them and said, ‘Hey, your filter or your engine oil needs to be changed.’ And they were scratching their heads, saying, ‘Hey, I’m only 50% into my recommended service interval. It can’t be the case that my oil has gone bad.’ So that’s where the customer did collect an oil sample and tested it in a lab. And it was a big ‘aha’ moment for them, saying, ‘Hey, I would not have known my duty cycle had changed due to cold weather and high idle time. And I’m glad there was a FleetguardFIT solution on there, which alerted me to change the oil.” That’s a real-world example that we have working with the customer.”

This article was sponsored by Fleetguard. For more information, visit FleetguardFIT.com, and fill out the form on the page to get in touch with experts on the products.