It’s probably not a surprise to hear that a large number of the most common issues with today’s diesel engines involve aftertreatment systems. Recently, Fleet Equipment discussed the causes of problems such as excess regeneration activity and how to determine if the regeneration frequency with their engines is within a normally accepted range. Our panels of experts also talked about how fleets can go about diagnosing aftertreatment systems, the guidelines they should use, and the tools available to them.

Panel of Experts

- Ryan Vaughn, customer support manager, Cummins Inc.

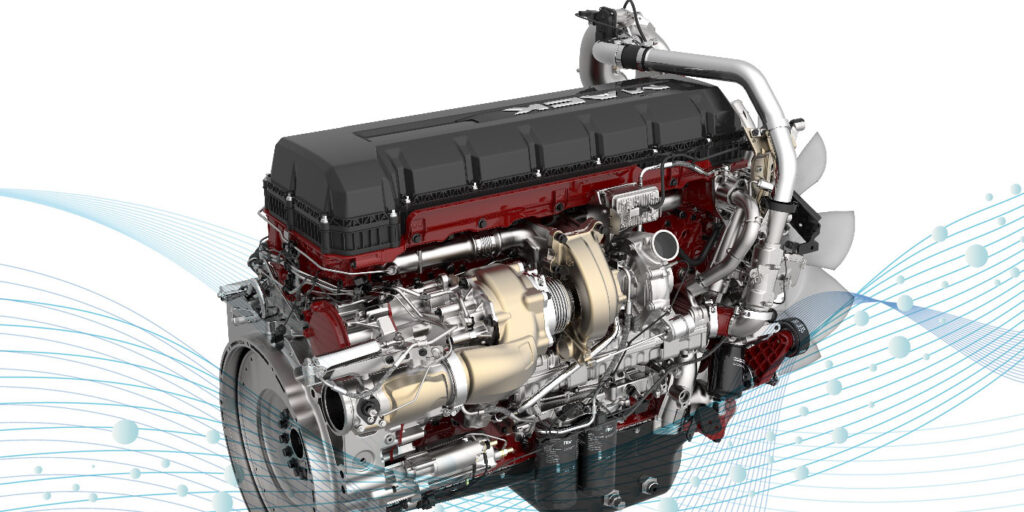

- Andrea Brown, director of product management–complete powertrain, Mack Trucks

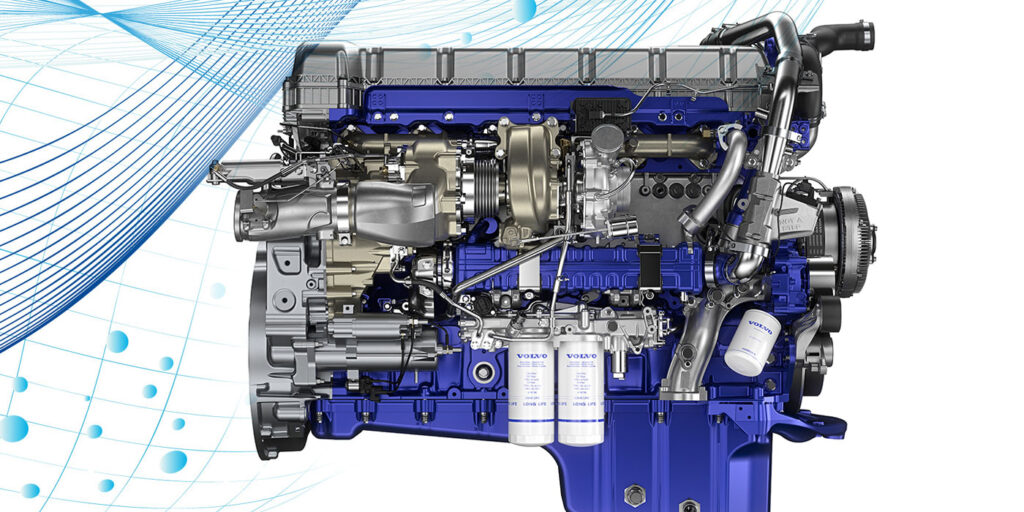

- Ashley Murickan, product marketing manager, Volvo Trucks North America

Fleet Equipment (FE): What are the most common aftertreatment system problems that can cause an excess of regeneration activity?

Vaughn: The most common issue that can cause excessive regeneration activity is when the duty cycle does not allow for passive regeneration events. When high idle times, frequent stop and start events, lack of consistent engine and vehicle speeds, or light engine loads frequently occur in daily operation, the Diesel Particulate Filter (DPF) is more likely to fill up, and a stationary regeneration will be needed. If stationary regeneration is consistently delayed, more aftertreatment issues occur. Additionally, any contaminants that make their way downstream to the aftertreatment system can impact the system’s overall health.

Brown: The most common root cause we have seen for frequent regenerations is heavy ash loading on the DPF because the filter is not cleaned properly or according to the prescribed frequency. Another potential reason for excess regeneration activity is incomplete regeneration cycles that usually result from continuously low exhaust temperatures during primarily stop and go operations, or in cold weather where the system is not able to sustain a high temperature long enough during the application cycle to complete the procedure.

There have also been a few cases of high silica content in fuel causing frequent regenerations. Other possible causes can include poor fuel quality, poor DEF quality, improper DEF concentration, leaks in the exhaust stream, improper backpressure and improper maintenance of aftertreatment system components.

Murickan: In addition to incorrect fluids or coolant consumption or a major system failure, excessive idle time and frequent starting and stopping can have a direct impact.

FE: How can fleets determine if the regeneration frequency with their engines is within a normally accepted range?

Murickan: Regeneration frequency is dependent on duty cycle. Stop-and-go city driving can have a higher regeneration frequency. Highway driving, with high exhaust temperatures, may have a lower frequency of regeneration. Regeneration frequency is also dependent on fluids, including fuel, oil and coolant. Any coolant consumption by the engine can increase regeneration frequency. The same is true for incorrect fuel or oil, or any engine stress or failure resulting in increased oil consumption.

Other engine failures or maintenance gaps can have an impact as well. EGR or fuel system component failures can result in higher soot or fluid deposits on the DPF causing an increase in regeneration frequency. Aftertreatment hydrocarbon injection system failure can impede normal operation, resulting in parked regeneration requests.

Vaughn: Fleets can determine if the regeneration frequency with their engines is within a normally accepted range by consulting OEM tools and running an ECM report. The key for regeneration frequency is to look for consistency between events and how often they occur on an engine hour basis. To determine the appropriate length of time before DPF cleaning or exchanging is required, consult the Owners and Operators manual for the specific engine.

Brown: All regeneration and sublimation frequencies can vary according to the specific application in which the vehicle is used. Applications where the exhaust temperatures remain cooler may experience more often regeneration cycles. Cold weather settings can include automatic periodic heat modes that can sound like a regeneration triggered automatically and be perceived as frequent regenerations.

FE: Do you advise fleets to have any special tools or technologies for diagnosing aftertreatment system issues?

Vaughn: When diagnosing aftertreatment system issues, it is recommended that fleets follow exhaust system diagnostic procedures in the Cummins online service manual on QuickServe and to use the Cummins INSITE engine diagnostic program to validate ECM data. There are also technical service bulletins, fault code troubleshooting guides and the Aftertreatment Diesel Particulate Filter – Excessive Automatic and/or Stationary Regeneration Symptom Tree.

Brown: The recommended tool for diagnosing Mack engines is our Premium Tech Tool, a Windows-based diagnostic application designed to test, calibrate and program engine parameters. PTT has the capability to show which type of regeneration is being requested, as well as accumulated data from the DPF pressure sensors that can help diagnose either heavy ash loading or other issues that would lead to frequent regenerations.

Murickan: Using the Volvo Trucks Tech Tool will help with understanding what is causing the regeneration request. It is also important to collect data of when any increased regeneration frequency began and what preceded it, and to read and evaluate fault codes when failures with the fuel system, EGR system, turbocharger, etc. occur, and to make sure all sensors are functioning properly.