During the Technology and Maintenance Council (TMC)’s Fall Meeting and Transportation Technology Exhibition, TMC and Decisiv Inc. released their most recent North American Service Event Benchmark Report, which showed an increase in parts and labor costs over the first six months of 2021. The reports, which cover power unit costs in nine top Vehicle Maintenance Reporting System (VMRS) System Level Code categories are compiled from more than 600,000 monthly service maintenance and repair operations conducted across nearly 5,000 service locations using Decisiv’s SRM (Service Relationship Management) platform.

Between the first and second quarters of this year, the benchmark data on more than 7 million vehicles in the U.S. and Canada showed that labor costs for repair and maintenance increased 2.6% and parts costs increased by 2.8%.

The report cited economic growth that has led to a rise in freight volume and demand for carrying capacity, which is also being driven higher by the need to replenish supply chains that have been depleted due to manufacturing and distribution shutdowns during the pandemic, for the cost increases. Decisiv President and CEO Dick Hyatt pointed out that for fleets, that activity has increased vehicle mileage as well as meant the addition of more trucks.

“Both of those factors drive up service activity,” Hyatt said, “but we do not see a drop in efficiency and productivity taking place among fleet maintenance or service provider operations. They are continually striving to maintain the highest possible levels of asset performance and uptime.”

A key means of achieving that objective is the use of vehicle telematics in shops.

“Remote diagnostics allow fleets to maximize uptime, decrease repair costs and improve their overall maintenance plans and routines,” said Scott Bolt, vice president of product management at Noregon. “Remote diagnostics and in-shop systems can work in unison. By using the two technologies together, fleets can access information in real time that helps them understand what is wrong with the truck and the best method for managing its current issues.

“Fleet management must adopt processes that supplement their in-shop maintenance with remote diagnostics,” Bolt continued. “Using remote diagnostics, technicians can begin to triage a vehicle before it arrives at the shop, but only if fleet personnel pass along vital diagnostic information.”

During the TMC meeting as well, Trimble Transportation announced integrations with its TMT Fleet Maintenance software designed to improve that kind of connectivity. One of those is with Uptake Fleet, which provides predictive maintenance insights based on real-time fault data. The integration will enable the information to be shown as Work Pending in the TMT software.

Another new integration with TMT connects the Norgeon JPRO Professional diagnostic solution that provides technicians with vehicle data, fault code descriptions, troubleshooting steps and bi-directional tests for all makes and models of commercial vehicles. The JPRO integration allows TMT Fleet Maintenance users to upload vehicle and diagnostic information for repair orders.

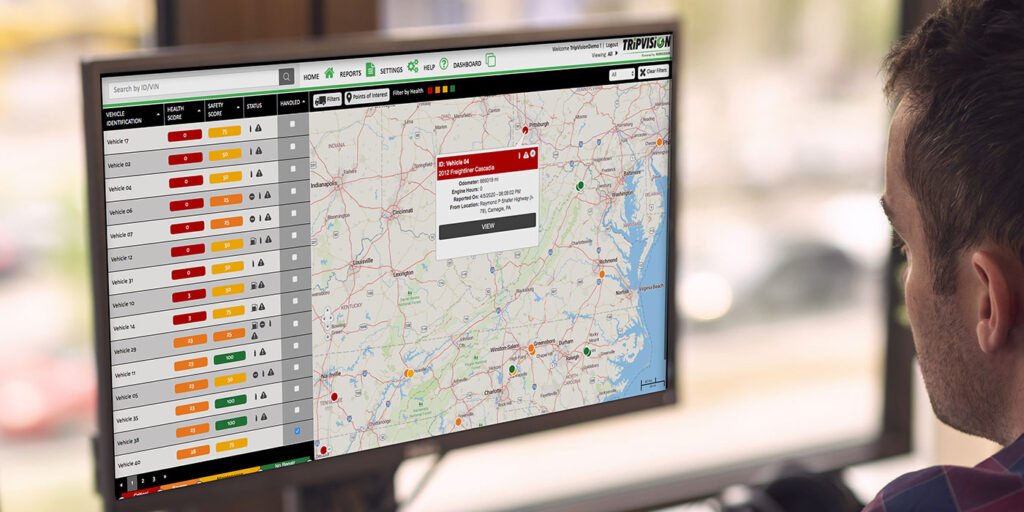

Available as well from Noregon is TripVision Uptime. The remote diagnostic application provides diagnostic reports and can be set up with configurable alerts. In conjunction with JPRO, it can also enable fleet managers and technicians to look for recurring issues.

Offered by Nexiq Technologies is eTechnician 2.1, a PC-based diagnostics solution for engines, transmissions, brakes, bodies and chassis, and other systems on light-duty to Class 8 diesel powered vehicles. The company says that eTechnician can also be configured with an optional subscription to the company’s RepairConnect diagnostic information system, which provides access to step-by-step test and diagnostic procedures, component locators and wiring diagrams.

Shop diagnostic technologies are also being connected to systems from vehicle and major component manufacturers.

Detroit Connect Virtual Technician, a remote diagnostic system for Freightliner and Western Star trucks equipped with Detroit engines, relays fault details to fleets via email or a notification in the Detroit Connect portal. If the fault is critical, the system transmits data to the Detroit Customer Support Center for further analysis.

Cummins Connected Diagnostics connects engines to the manufacturer for monitoring and diagnosis of system faults and informs fleets through mobile app, email or web portal alerts.

Volvo Remote Diagnostics, standard in every new truck from the OEM, monitors Volvo engines, aftertreatment systems and I-Shift transmissions, and provides information on the cause of fault codes.

Mack Trucks offers GuardDog Connect, which identifies fault codes and diagnostic needs, and it forwards diagnostic information to your nearest service center.

Kenworth TruckTech+ Remote Diagnostics sends a notification to fleet managers and designated dealers when an engine fault code is triggered.

Peterbilt SmartLinq Remote Diagnostics instantly analyzes over 900 engine and emissions systems fault codes and provides real time notifications and recommendations to fleet managers via the PACCAR Solutions portal.

The International Truck OnCommand Connection remote diagnostics solution supports all commercial truck makes and models with vehicle fault code reporting and severity ratings and fault code action plans through more than 30 integrated telematics service providers.

Hino Insight remote diagnostics alerts fleets and dealers about customizable alerts in real time along with live diagnosis, severity reporting and next step recommendations.

“One of the greatest impacts remote diagnostics has on uptime is its ability to detect issues early,” said Noregon’s Scott Bolt. “Fleets can get ahead of vehicle problems by learning about them as they occur. Real-time diagnostics can also prepare shops for the truck’s arrival and ensure the proper bays, labor, and parts are available to correct the problem in a timely manner.

“Essentially, remote diagnostics are a first line of defense that greatly expedite the discovery and planning phases so in-shop technicians can focus on repairs.”