“Safety first.” Yes, it’s a cliché, but sometimes a cliché becomes that way for a reason, and certainly, for modern fleets, safety is of paramount importance. From the need to guard against the expensive costs of a crash to the simple responsibility of making sure those multi-ton Class 8 trucks are as safe for their neighbors to drive alongside as possible, safety is crucial in the trucking industry.

This is why more and more fleets are spec’ing advanced driver assistance systems (ADAS), and why every OEM now offers ADAS as a feature or option of either some or all of their new trucks.

As the technology continues to grow in popularity, ADAS is going to be crucial for technicians as well—to know the ins and outs and to be able to easily work on these systems is going to be one of the modern truck tech’s biggest jobs.

“As ADAS systems have continued to progress — becoming even more refined — the maintenance practices likewise need to be dialed in,” says Kristy LaPage, business manager for the commercial vehicle group at Mitchell 1. “The technicians need the information in order to properly repair or calibrate those systems.”

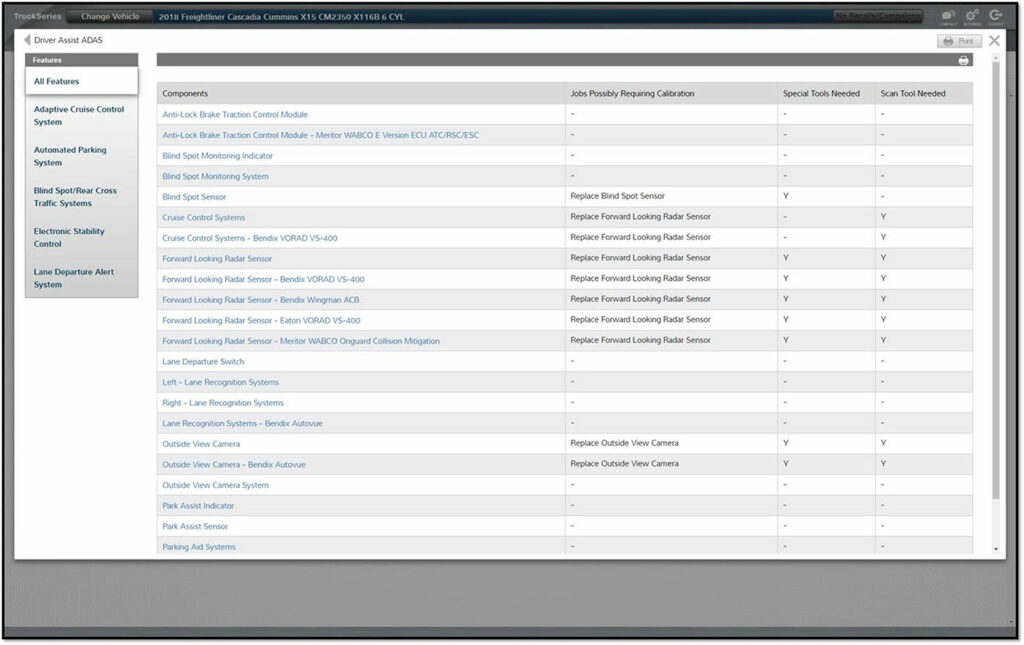

This is why Mitchell 1 has been adding features to its TruckSeries software to make this process as smooth as possible for technicians. The company recently added ADAS to its QuickLink feature, which allows technicians using the software to quickly and easily access useful, frequently needed information such as fault codes without going through multiple menus. This ADAS QuickLink navigates the user to a list of components in the ADAS system, presenting a consolidated view of the component/system names, jobs that may require calibration, special tools needed, or if a scan tool is required.

“Finding that information is not always the easiest thing,” LaPage notes. “Our goal at Mitchell 1 is not only to provide the content needed to correctly repair a vehicle, but also to make sure that the technician’s time is well spent working on the truck and not looking for content in their software. In order to do that, we put a lot of thought and care into navigation in TruckSeries and how to make it easy to find information and get in and out of the system quickly.

“So whether that’s the parking system, the stability control lane departure, if it’s equipped on that vehicle, you can either look at all of the features that are available for that particular vehicle, or you can type into the program specifically. As an example, if you select the adaptive cruise control system, the system will take you directly to the listing of those different components and the systems that are affected,” she explains. “TruckSeries will also tell you if a special scan tool is needed to carry out diagnosis and repair. Getting the calibrating information easily and quickly is just a great advantage.”

Among the benefits of this feature: TruckSeries is an all-makes software system, so it has information for each ADAS manufacturer’s products; and when new information comes in or updates are made, the system is updated as well.

Click here for more information on Mitchell 1 TruckSeries.

This article was sponsored by Mitchell 1.