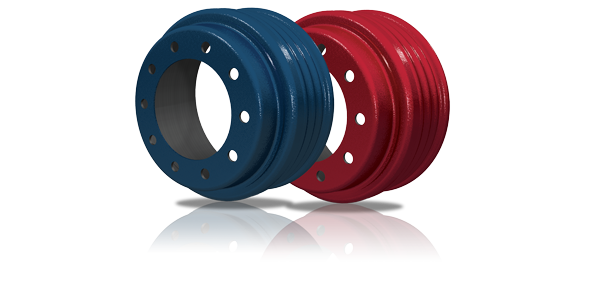

It’s easy to take brake drums for granted. The tried-and-true braking component has been a staple of truck safety systems for decades, but that doesn’t mean that brake drum technology hasn’t advanced. In fact, you’d be surprised how much you can impact fuel efficiency with the right brake drum spec.

“Fleet managers have a tremendous amount of ability to influence the truck’s fuel efficiency with the right brake drum,” said Jeff Bates, general manager of Motor Wheel, a brake drum and brake adjuster manufacturer that has roots stretching back to 1898 and has continually improved upon its brake drum technology ever since.

Bates noted how savvy fleet managers have become at squeezing every drop of ROI out of their equipment selection, and brake drums are no exception.

“The key way to improve fuel efficiency through brake drum selection is by reducing weight,” he explained. “Truck OEM Navistar has noted that when you increase your vehicle weight by 1,000 lbs. you decrease fuel economy by half a percent. So when it comes to our brake drums, we utilize high-performing, weight-saving materials that increase fuel savings on trucks and trailers. Our CentriFuse Motor Wheel brake drum, for example, can save up to 232 lbs. on a tractor and trailer combination over a typical full-cast drum.”

ROI is definitely a top spec’ing consideration but when it comes to a safety-critical component like brake drums, safety performance is paramount. After all, ROI also comes from ensuring that your trucks brake properly with the expected stopping distance every time the driver uses the service brake.

“Lower quality drums that are made from basic cast iron that doesn’t contain an abundance of alloys that aid in heat transfer and other performance characteristics can lead to things like brake fade,” Bates explained. “As a braking system is used frequently, heat builds up and the lower-quality drum expands. That results in increased stopping distance and the potential for the brake adjuster to over adjust on the vehicle.”

Not only does that present drastic safety consequences, but it also means increased downtime and maintenance expenses as trucks need to be brought in more often for unplanned brake service.

“That speaks to drum wear as well,” Bates added. “Drums made of lower quality materials will actually accelerate lining wear. Additionally, localized hard spots in the brake drum are also a concern–they can be felt by the driver. That ties into driver health and comfort. A lot of folks might not take that into consideration when looking at brake drums.”

Bates noted that Motor Wheel uses proprietary alloys in its drums that pull heat away from the braking surface. “That increases the longevity of the brake lining and increases the life of the braking surface on the drum.”

Motor Wheel brake drums are also OEM-approved on all trucks and trailers. Motor Wheel is a brand of Hendrickson.

Click here to learn more about Motor Wheel brake drum and brake adjuster technology.

This article was sponsored by Hendrickson.