Environmental-related regulations and requirements are going to continue increase, and not just in California. Across the United States, 403 cities have signed the Paris Agreement, a global response to the threat of climate change. What’s that mean for you as a fleet manager? If the California Air Resources Board (CARB) rule that aims to have roughly an estimated 300,000 vehicles by 2035 is any indication, it means that you’ll likely be spec’ing equipment with emissions requirements in mind sooner than you think.

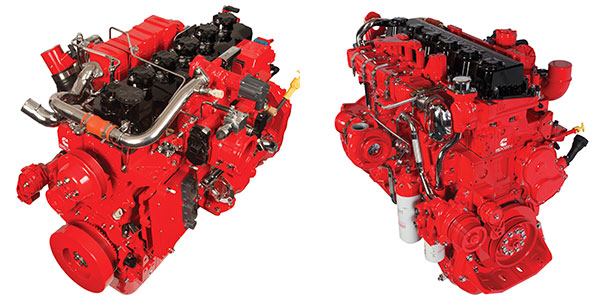

“As we look toward the future, we know there’s an enormous amount of anxiety about which technology fleets want to adopt,” said Hugh Donnell, North American OEM truck and market segment leader, Cummins Westport Joint Venture, who noted that while Cummins continues to invest in diesel engine technology (manufacturing 1.4 million diesel engines last year worldwide), Cummins also offers near zero emission natural gas engines, and the OEM is also heavily invested in developing hydrogen fuel cells and battery electric powertrains. “As we move forward, everyone is going to have to figure out which technology works best within their specific application.

“The days of having one powertrain technology dominate all of the different commercial goods movement applications is a long way off.” Shippers must continue to be profitable in their business, so the technology they adopt must be competitive with the current technology while achieveing zero or sub-zero emissions.

It’s easy to get caught up in new technology like electric powertrains to meet emissions requirements, but it’s not your only option. The key phrase to a lot of these rules is “zero emissions or sub-zero emissions.” That puts renewable natural gas engines on the table. So here are three reasons renewable natural gas is worth a look.

- It’s available today

As the headlines tout battery electric, hybrid-electric and hydrogen-electric technology, those technologies also come with plenty of questions. How will the cost per mile compare with the current technology? Are all new goods movement technologies federal and state subsidy dependent? If so how much and for how long? How will the range meet your application needs? Where will you fuel it? How long will it take to “refuel”? What about lifecycle expectations? With renewable natural gas trucks, OEMs and suppliers have answers. Of course, the answers (like all fleet equipment) are dependent on your application.

“As it relates to municipalities,” Donnell cited as an example, “they work more like a closed-loop economy, and in that sense, most have access to renewable natural gas. It’s a resource that is readily available for municipalities and cities in local or regional landfills. For those companies that are operating Class 8 trucks, they find that renewable natural gas is readily available to meet their application cycles.”

If you’re operating in a location that is focusing on driving down its overall emissions or it’s a corporate initiative within your fleet, you can put a renewable natural gas-powered truck to work today and start reducing your overall emissions footprint with immediate effect.

But by how much? That brings us to number two.

- It’s also the lowest emission powertrain available today

Sure, zero-emissions is zero-emissions, but the reality is that wider adoption and use of battery electric and hydrogen-electric trucks is a long way out. Add natural gas trucks to your fleet today and you can reap the benefit of these bullet points:

• NOx is 90% below current EPA standards.

• Particulate matter is below 90% current EPA standards.

• CO2 equivalent is 16% below current EPA standards.

Noticing a trend? And “below current EPA standards” isn’t the only thing that’s lower.

- Lower emissions-related maintenance costs

Three letters: DPF. If a mention of the aftertreatment system sends service-cost shivers down your spine, you’re not alone. Diesel aftertreatment-related maintenance issues are a thorn in nearly every fleet’s side. Guess what doesn’t have a complicated aftertreatment system?

“For those fleets operating diesel engines, you have aftertreatment systems that require fluids and regular cleaning of DPF in active and passive regeneration—natural gas has none of that,” Donnell said. “Natural gas is a maintenance-free exhaust system. By that standard, it has a lower cost and complexity that you currently must deal with.”

Click here to watch an on-demand webinar to learn more about natural gas.

This article was sponsored by Cummins. For more information, please visit our website at www.cummins.com.